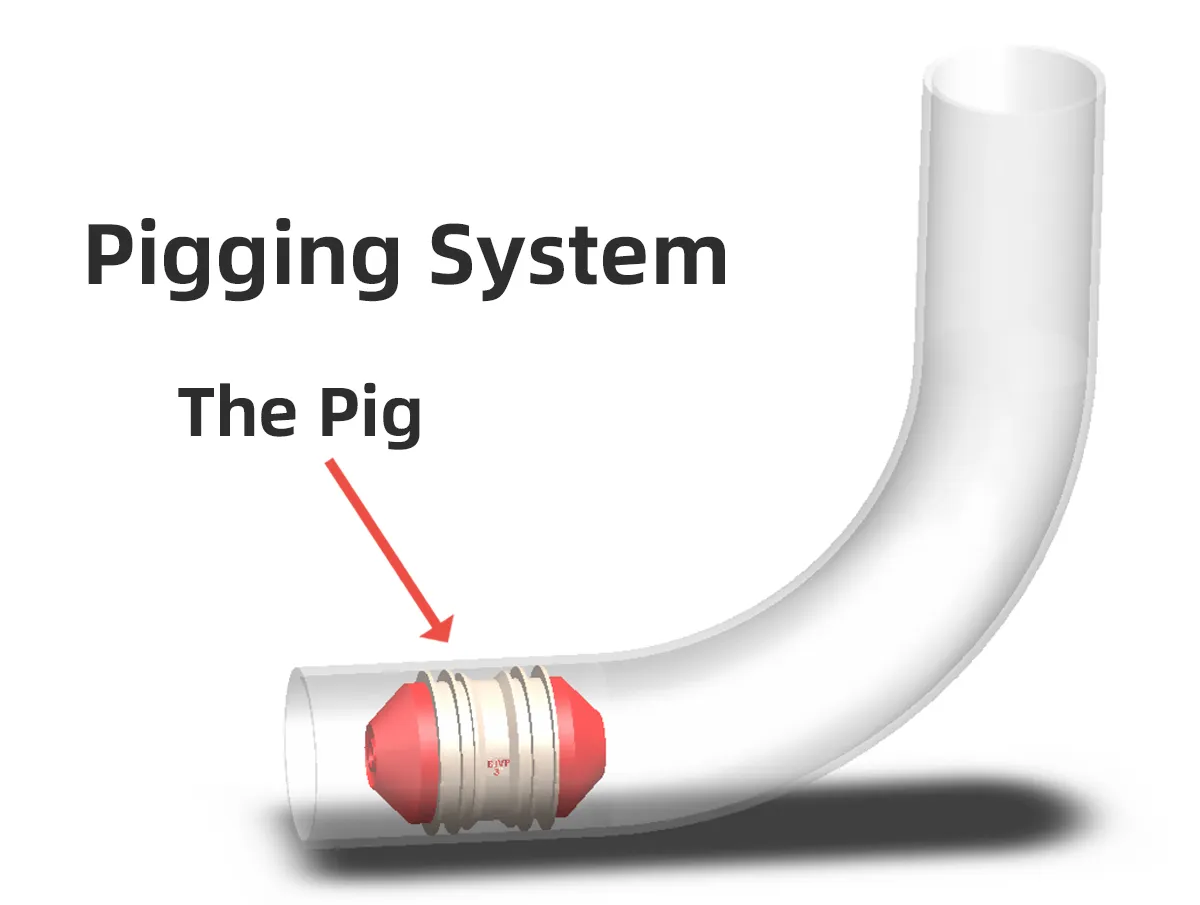

Pipeline Pigging Cleaning Pig is an elastic device slightly larger in diameter than the pipeline inner diameter, made from materials like rubber or polyurethane. It is typically cylindrical with tapered ends to easily pass through elbows. Driven by internal media (such as gas or liquid), the pig effectively scrapes and recovers products attached to the pipe walls, directing them to a designated recovery point. It often features advanced sensors and control systems that monitor the pig’s position and speed in real-time, enabling precise control and automation for efficient cleaning, ensuring the pipeline stays clear and clean. This is an essential component in industrial pipeline pigging cleaning systems.

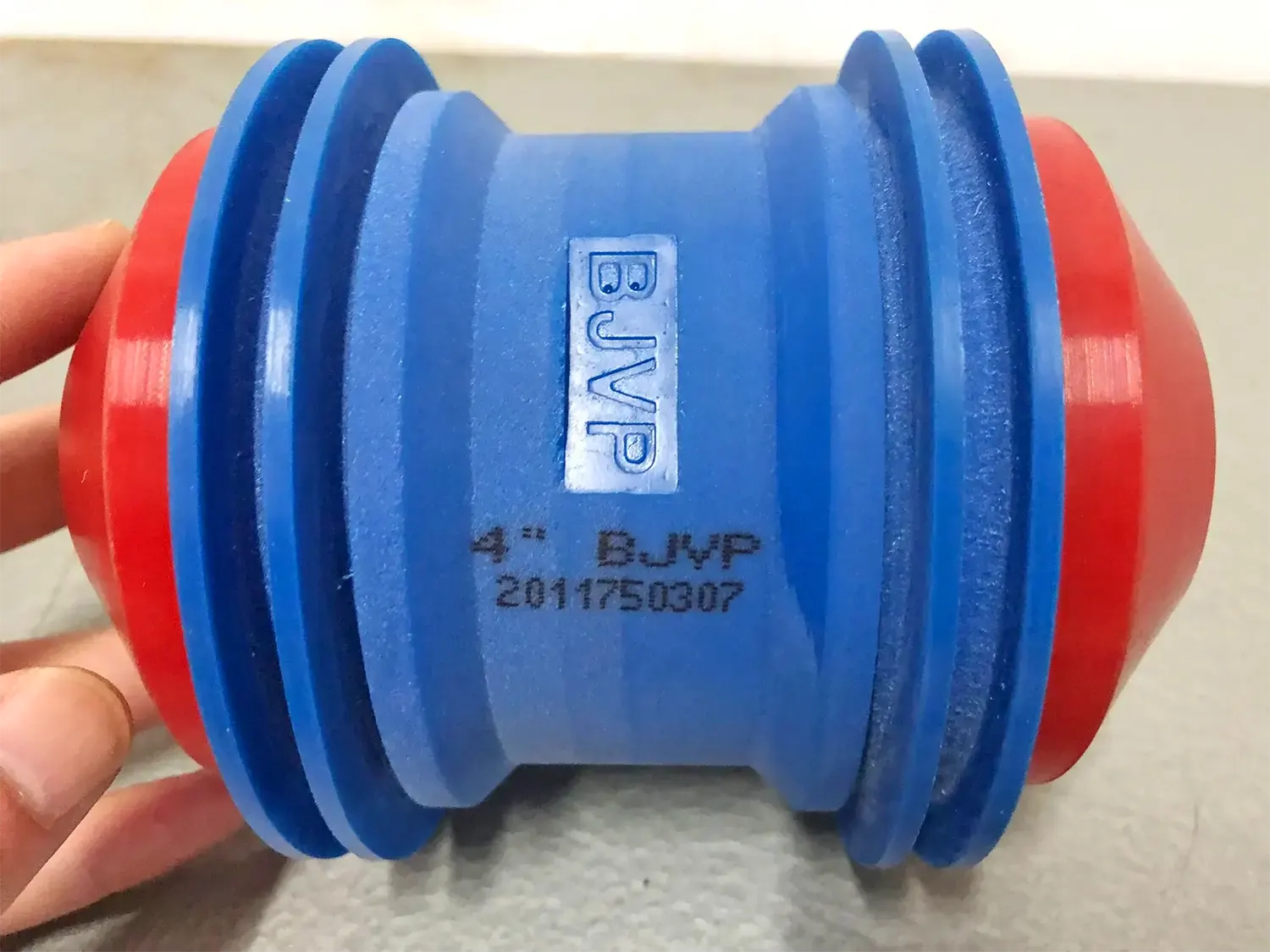

BJVP Standard Industrial Magnetic Pipeline Cleaning Pig is equipped with a high-strength magnet, efficiently recovering residual materials inside the pipeline, ensuring fast and reliable cleaning operations. The pig body is made from abrasion-resistant polyurethane, offering excellent corrosion and wear resistance. It features a removable structure design for easy replacement of worn components, enhancing maintenance efficiency and extending the service life.

The magnetic pipeline pigging pig is typically available in sizes ranging from 2 inches to 8 inches. For specific industries, sizes like 1.5 inches and 2.5 inches are available, with further customization in size and material to meet specific operational conditions or customer requirements. It is widely used in pipeline cleaning operations across industries such as petrochemicals, coatings, food, and pharmaceuticals. This pig is designed to enhance pipeline cleaning efficiency, reduce product waste, and prevent cross-contamination.

BJVP Magnetic Pipeline Pigging Pig offers outstanding durability, reliability, and customization, making it an indispensable core component for industrial pipeline cleaning and product recovery systems.