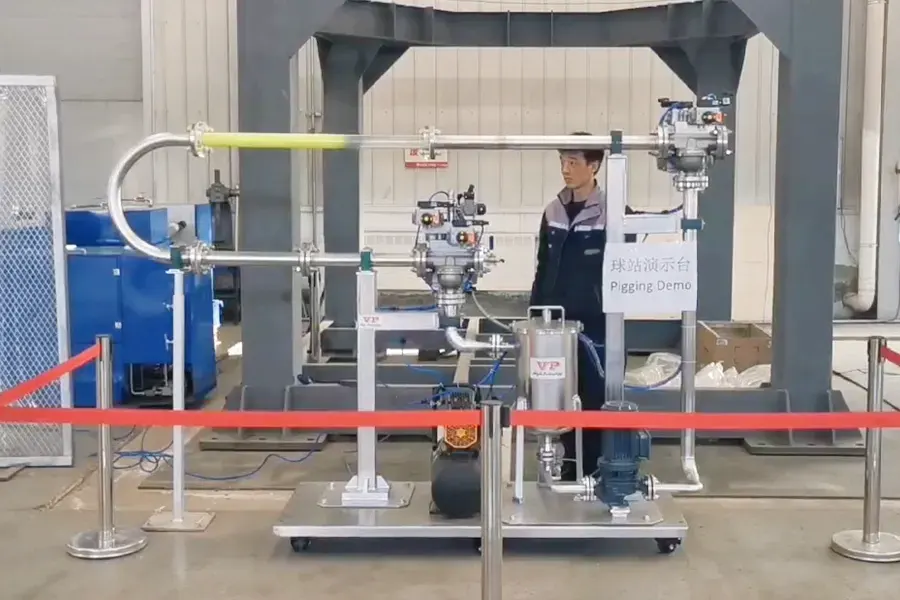

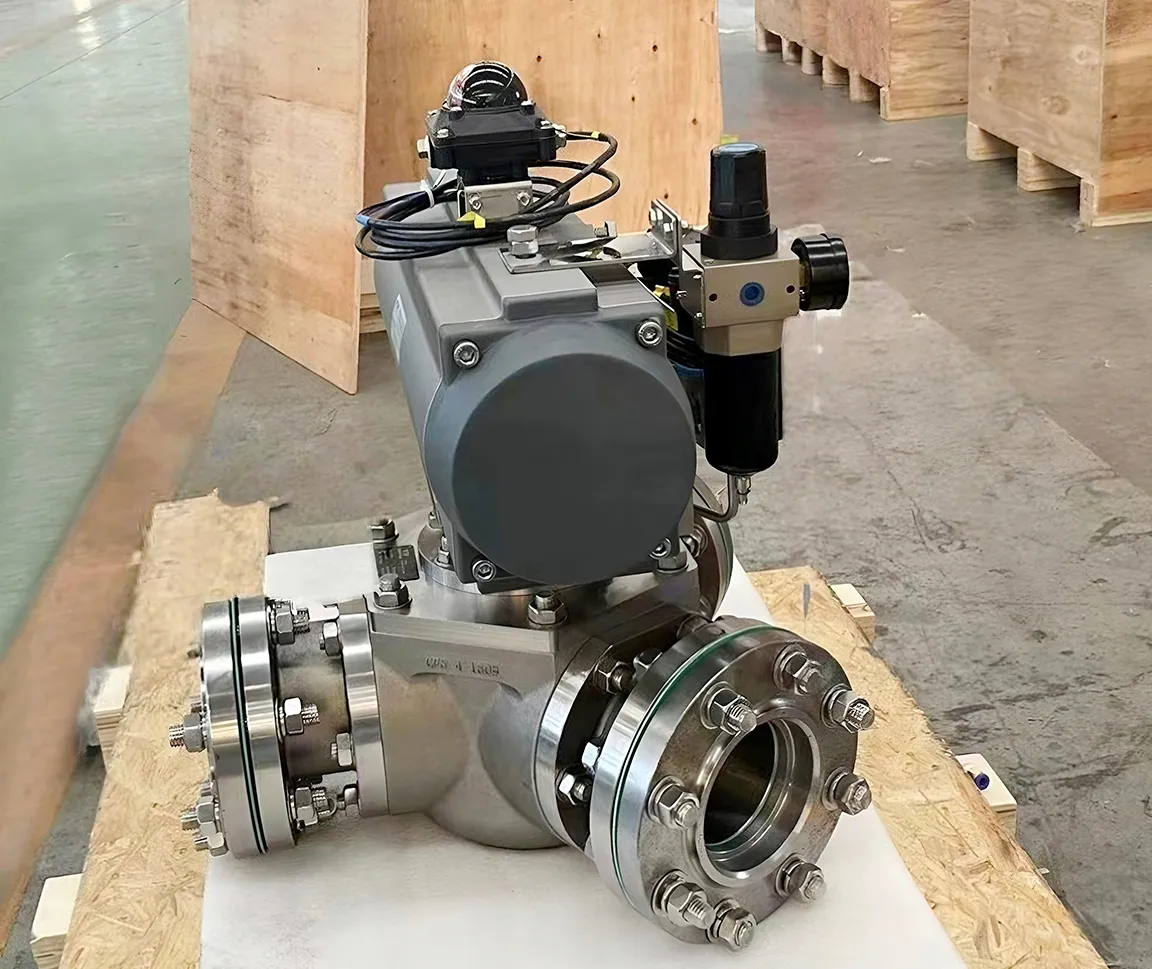

The 3-Way Distribution Valve is specifically designed for complex pigging systems. It allows pig passage and enables pipeline switching, overcoming the limitations of traditional “point-to-point” transfer. It facilitates flexible material transfer from a single source to multiple destinations (two or more) and enables thorough pipeline cleaning. It can perform the functions of both simple launching/receiving stations and intermediate stations. Its operation principle resembles a railroad switch—only two ports are ever connected simultaneously (either left or right, depending on the valve position). By precisely controlling the valve actuation, the PIG’s (Pipeline Inspection Gauge) travel path can be altered, directing it accurately to any designated destination among multiple endpoints. This design optimizes material distribution, enhances pipeline cleaning efficiency, and ensures flexible and precise pigging operations. It is an indispensable key component in complex process piping systems.

Core Functions & Advantages

1. Precise Multi-Directional Flow Distribution

- Core Function: Acts as a pipeline “switch,” reliably guiding pigs (PIGs) and material flow to any pre-set destination pipeline.

- Operating Principle: Maintains only two connected ports at all times, ensuring optimal flow paths and streamlined pipeline layout.

- Pig-Passable Design: Proprietary full-bore structure ensures smooth pig passage through the valve.

2. Significant System Performance & Cost Optimization

- Overcomes Single-Point Limitations: Easily meets complex process requirements involving multiple input/output pipelines.

- Reduced Piping: Minimizes redundant pipe runs and total length (maximizing shared lines), lowering initial investment and space requirements.

- Extended Pig Life: Optimized flow paths reduce wear, increasing pig service cycles.

- Energy Savings: Shorter paths and fewer bends significantly reduce driving medium (gas/liquid) consumption during pigging.

3. High Reliability

- Robust construction ensures long-term, stable operation.

- Anti-fouling design handles materials prone to sticking or sedimentation.

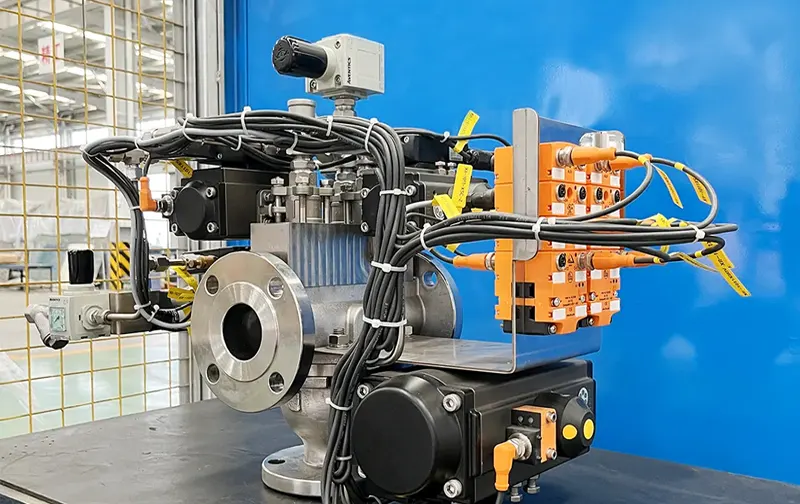

- Precise actuation (pneumatic/hydraulic/electric) guarantees dependable operation.

Solves Core Challenges

- Eliminates “point-to-point” transfer limitations.

- Minimizes product residue in pipes & valves, reducing contamination risk.

- Significantly lowers total pigging system costs (equipment, piping, energy, maintenance).

Key Application Areas

- Chemical: Chemical distribution to different reactors/storage tanks, cleaning circuit switching.

- Petrochemical: Multi-branch transfer and pigging of petroleum/petrochemical products.

- Any scenario requiring single-source to multi-destination transfer with efficient pipeline cleaning.

Value Proposition

- Flexibility: Builds efficient material transfer networks.

- Economy: Reduces Total Cost of Ownership (TCO) and operating expenses.

- Cleanliness: Ensures efficient pipeline evacuation, effectively lowering cross-contamination risk.

- Reliability: Industrial-grade quality for durable performance.

The BJVP 3-Way Distribution Valve is pivotal for enhancing pigging system efficiency and flexibility. Its pig-passable design and precise flow distribution capability directly address the shortcomings of traditional single-line systems, significantly shortening pipelines, extending pig life, saving driving medium consumption, and effectively reducing cross-contamination risk. It delivers an economical, reliable, and clean pipeline transfer solution for the petroleum, chemical, and related industries.