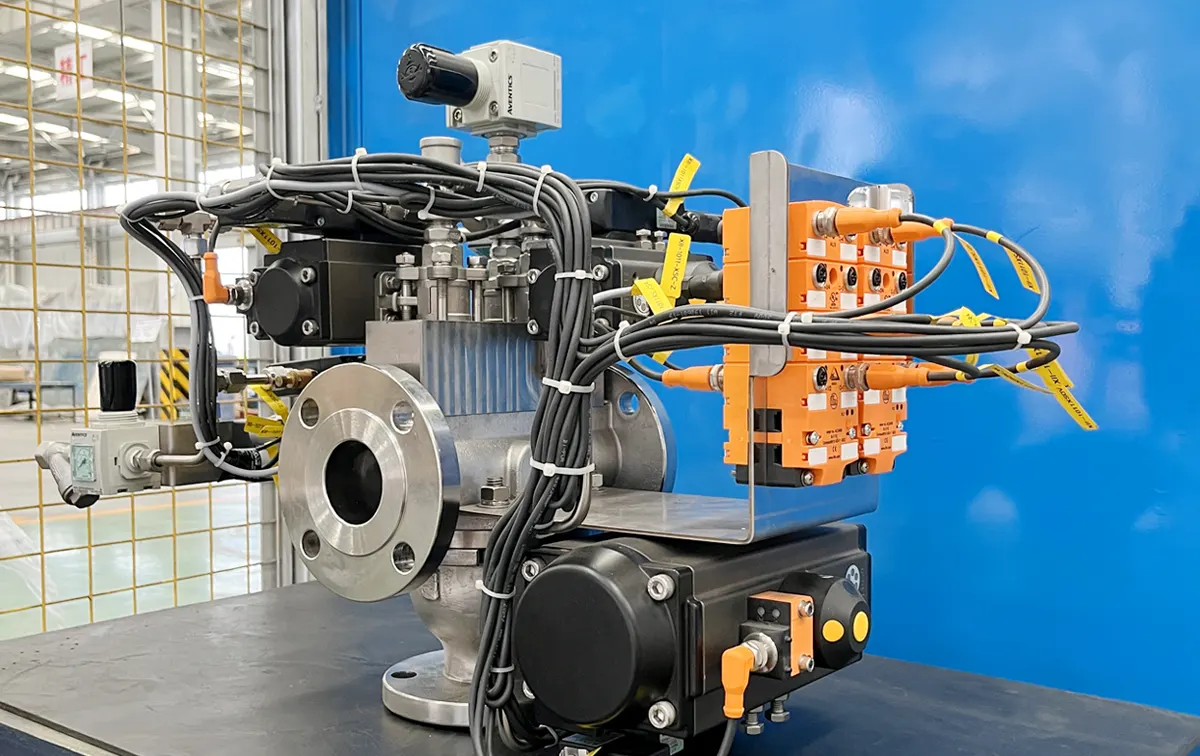

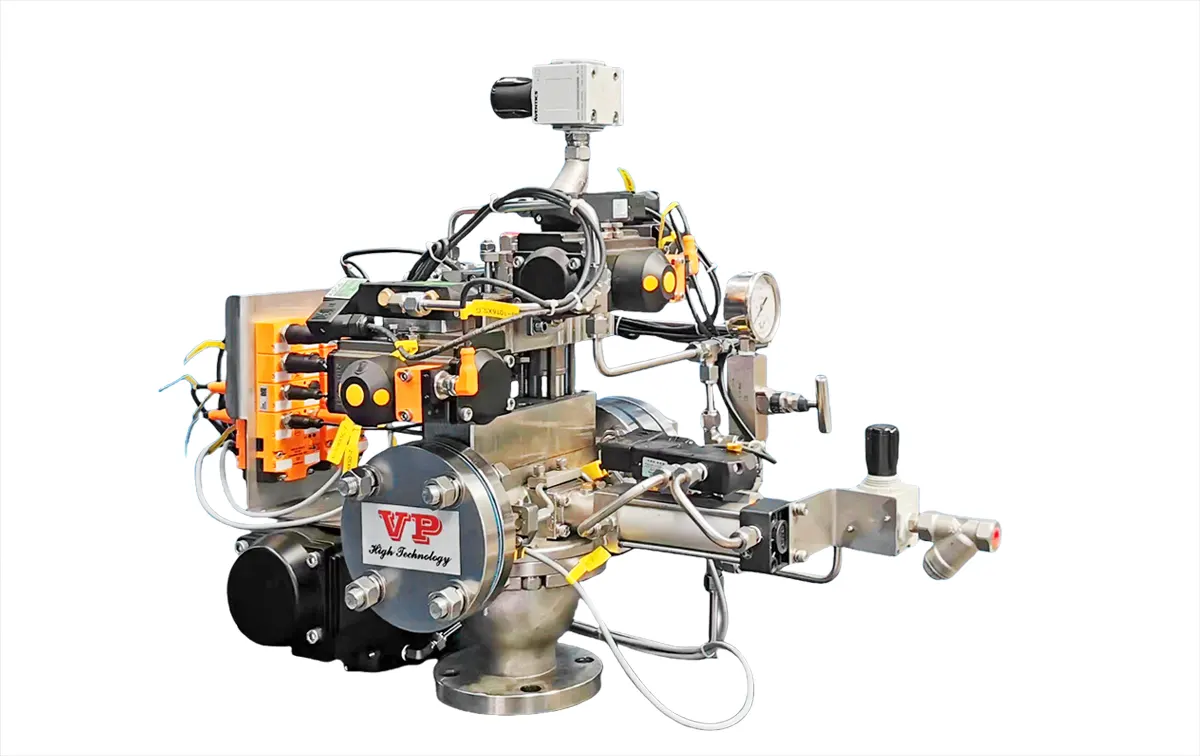

In pigging systems, the Pig Launcher (Launcher Station) plays the critical role of the “starting point” and “control hub”. It is far more than a simple valve; it is a highly integrated, feature-rich specialized valve assembly, specifically engineered for the safe and efficient management of pipeline pigging operations.

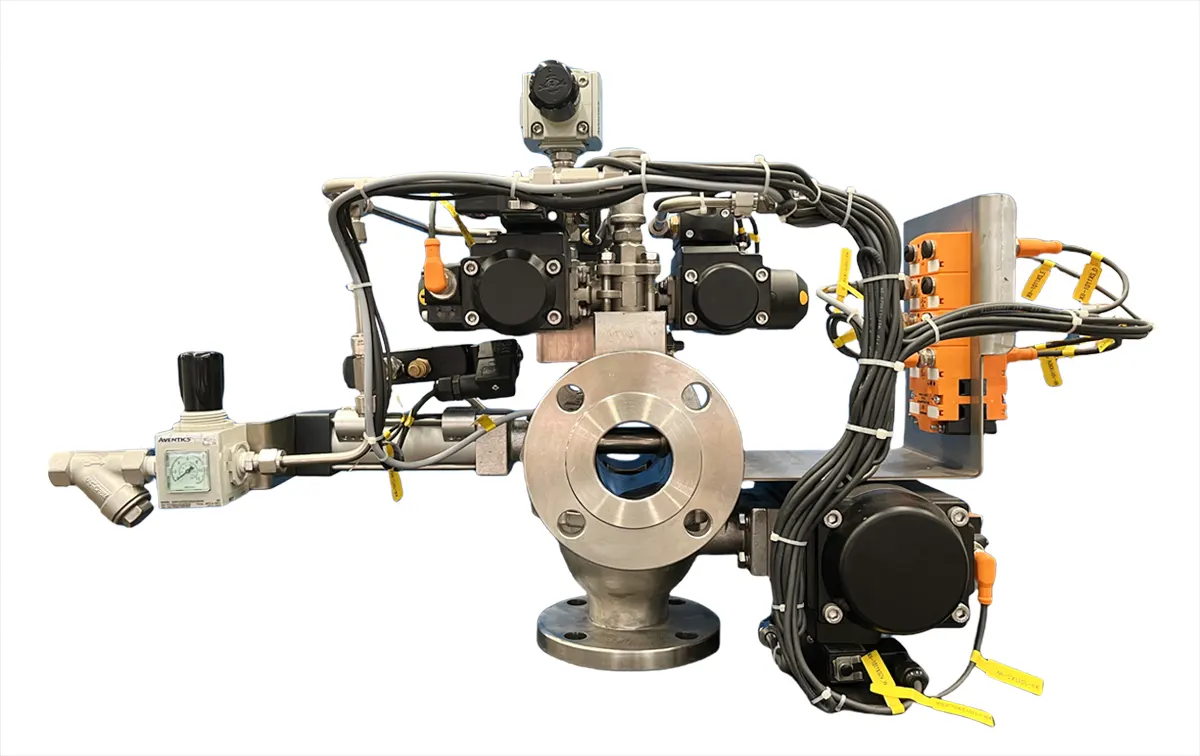

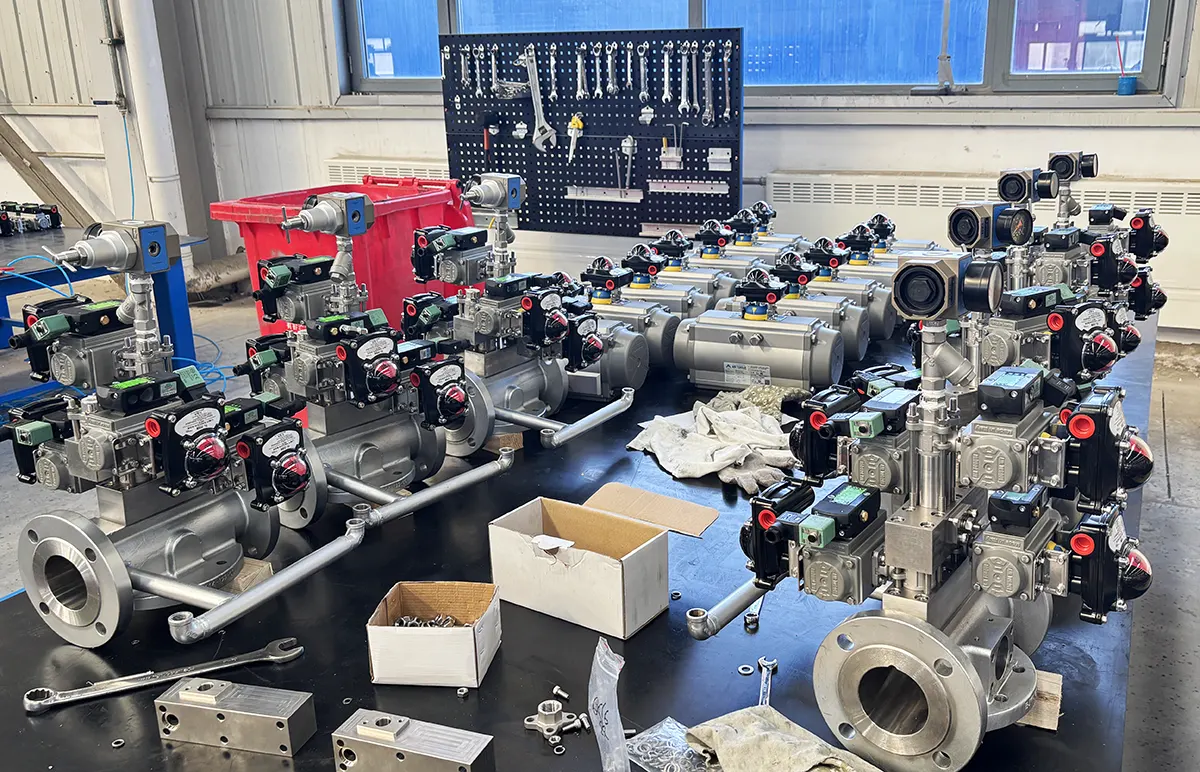

Some Pig Launchers are dedicated to sending only, while most pigging stations adopt integrated symmetrical designs with dual sending/receiving capabilities. This bidirectional configuration enables seamless pigging operations in both directions.

Trifecta of Core Functions: Power, Detection, Storage & Control

The core value of the pig launcher lies in its integration of three key functions, forming a reliable starting point for pigging tasks:

- Power Introduction: Serves as the system’s power inlet, responsible for the safe, controlled injection of high-pressure air, water, or other process fluid media into the pipeline. This propellant drives the PIG into the main pipeline, initiating the pigging run.

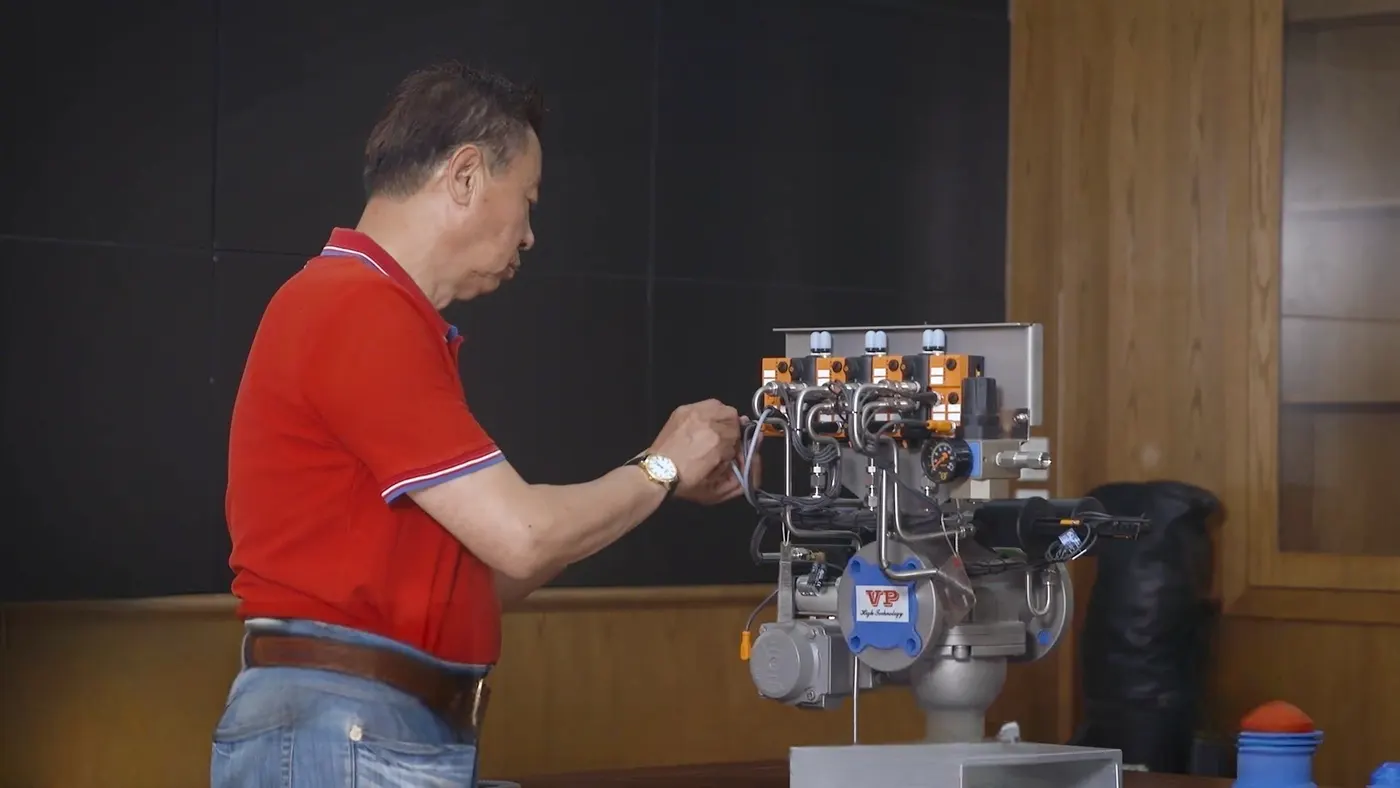

- Position Detection: Integrates advanced position detection devices (e.g., limit switches, magnetic position sensor) to accurately determine the PIG’s real-time position within the launcher barrel (e.g., loaded position, launch completion, storage position), ensuring process visibility and control.

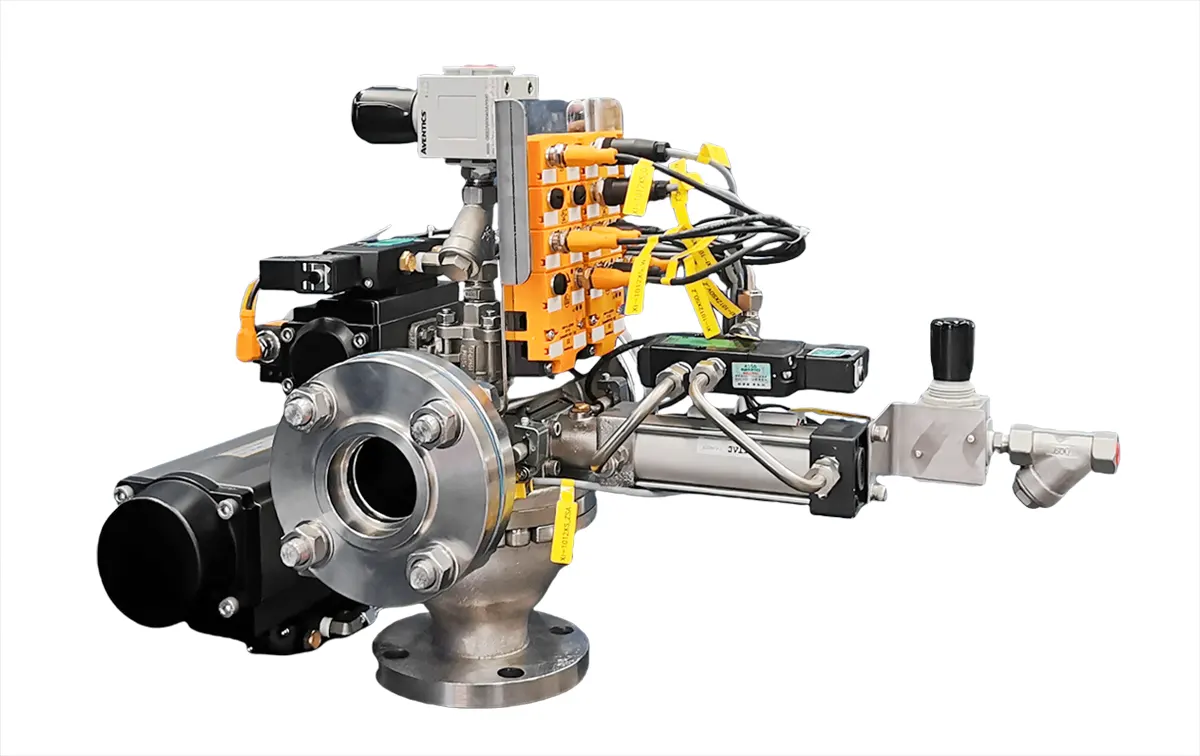

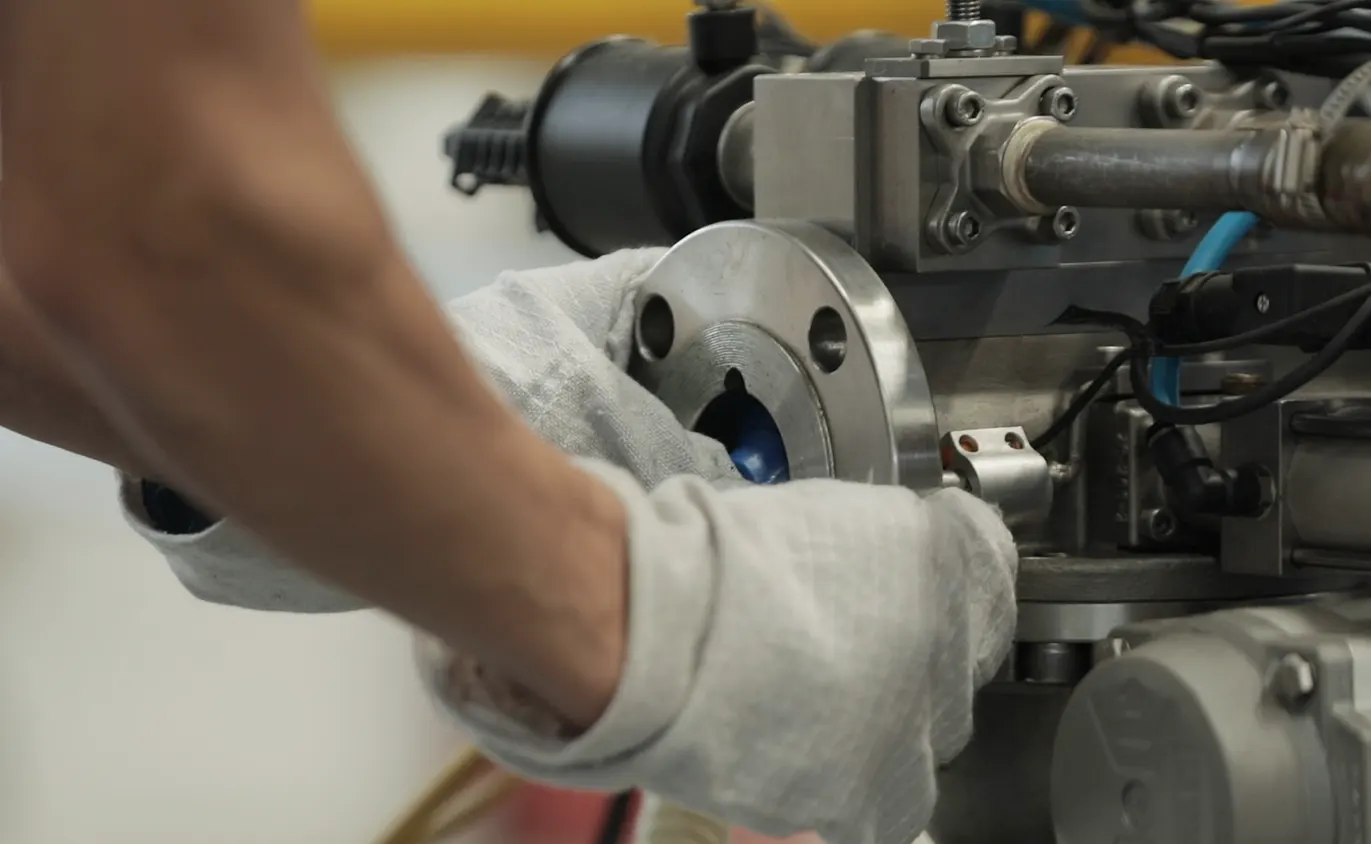

- PIG Storage & Handling: Provides a secure storage chamber for the PIG(s) (single or dual-pig systems). Features a dedicated quick-opening closure and PIG handling tool interface, enabling safe loading prior to operation and convenient, safe retrieval post-operation for maintenance or replacement.

Key Positioning & Operating Principle

The pig launcher is typically installed in series at the start of the pipeline, positioned downstream of the transfer pump (or power source). Its primary responsibilities are:

- Establishing a controlled pathway between the pipeline to be cleaned/inspected and the process media source/target vessel.

- Isolating the launcher barrel from the main pipeline via internal valves (main valve, bypass valve, vent/drain valve).

- Safely depressurizing the barrel, enabling the opening of the closure for PIG loading or retrieval.

- After closing the closure and pressurizing, opening the main valve to utilize the propellant media to smoothly launch the PIG into the main pipeline for pigging tasks.

Wide Application & Flexible Adaptation

The pig launcher is an indispensable component of any pigging system and must be used in conjunction with a pig receiver (receiving station) to form a complete PIG send-receive loop. To meet diverse customer requirements across industries (e.g., pressure rating, media characteristics, cleanliness standards, space constraints), we offer various pig launcher configurations:

- Standard

- Compact

- Online Maintenance (with dual isolation valves)

- Hygienic/Sanitary (for high-cleanliness applications)

Industry Applications

- Petrochemicals & Lubricants: Pipeline cleaning, product separation, reduction of product intermixing.

- Pharmaceutical Manufacturing: Supports CIP (Clean-in-Place) systems, ensuring batch-to-batch separation and compliance with GMP requirements.

- Food & Beverage: Efficient product recovery, guaranteed hygiene/safety, reduced waste.

Operation Sequence

- Loading: Load the PIG into the barrel via the quick-opening closure using dedicated tools and secure it in the launch position.

- Sealing & Preparation: Close and lock the quick-opening closure. Close the main valve, open the bypass valve for pressure equalization/pressurization.

- Launching: Upon equalization, open the main valve while controlling the bypass valve to introduce propellant, driving the PIG into the main pipeline.

- Completion & Retrieval: After the PIG reaches the receiver station, shut off the propellant source. Depressurize and drain the pig launcher. Confirm safety before opening the closure for maintenance or preparing for the next run (PIG retrieval typically occurs at the receiver station).

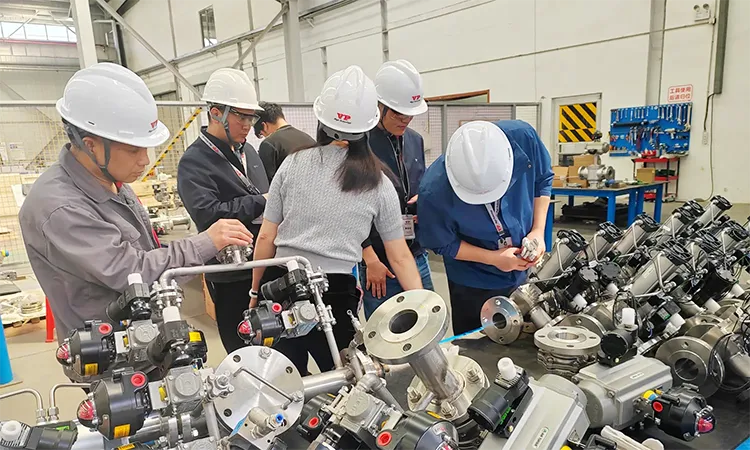

Core Product Advantages

- High Integration: Combines propellant inlet, PIG positioning, and secure storage in one unit, minimizing external components.

- Precise Control: Integrated position detection provides real-time PIG status, enhancing operational control and efficiency.

- Fast Maintenance: Modular design and dedicated handling tools significantly reduce PIG changeover time and maintenance costs.

- Custom Flexibility: Multiple specifications, end connections, and hygiene grades available to perfectly match your process needs.

- System Compatibility: Suitable for single or dual-pig systems, accommodating complex process requirements.

Key Technical Specifications (Subject to model variation)

| Parameter | Typical Range / Description |

|---|---|

| Design Pressure | 16Bar |

| Design Temperature | -30°C to +120°C (Material & Seal Dependent) |

| Bore Size (Barrel/Pipe) | 1″ to 8″ |

| Main Material | Stainless Steel (304, 316L), Non-Magnetizable |

| End Connections | Flange (WN, RF, RTJ), Threaded, TC Clamp |

| Valve Operation | Manual, Pneumatic, Hydraulic, Electric |

| Position Detection | Magnetic Proximity Sensors |

| Applicable Standards | Individually Certified per Customer Requirements |

| Hygiene Certification | Optional, Certified as per User Requirements |

Large Pig Launcher/Receiver Station

Conventional pigging stations typically use piping smaller than NPS 8. Units with piping NPS 10 or larger (e.g., 10-inch, 12-inch) are classified as large, integrated launcher/receiver barrels. These are primarily used in long-distance material pipelines (e.g., port-to-plant, railway station-to-plant). Installed at pipeline ends, they launch and receive pigs to perform pre-commissioning line cleaning and post-commissioning pigging tasks such as wax removal, oil sweeping, and scale removal.

Choosing a professional Pig Launcher means choosing the cornerstone of efficient pigging system operation!

We are committed to providing high-performance, highly reliable, tailor-made pig launcher solutions. Optimize your pipeline maintenance, enhance production efficiency, and ensure product quality and safety. Whether for demanding chemical environments, high-purity food/pharma applications, or long-distance oil transmission, our pig launchers are your trusted partner.

Contact us now for a professional pig launcher solution and technical consultation perfectly matched to your process needs!