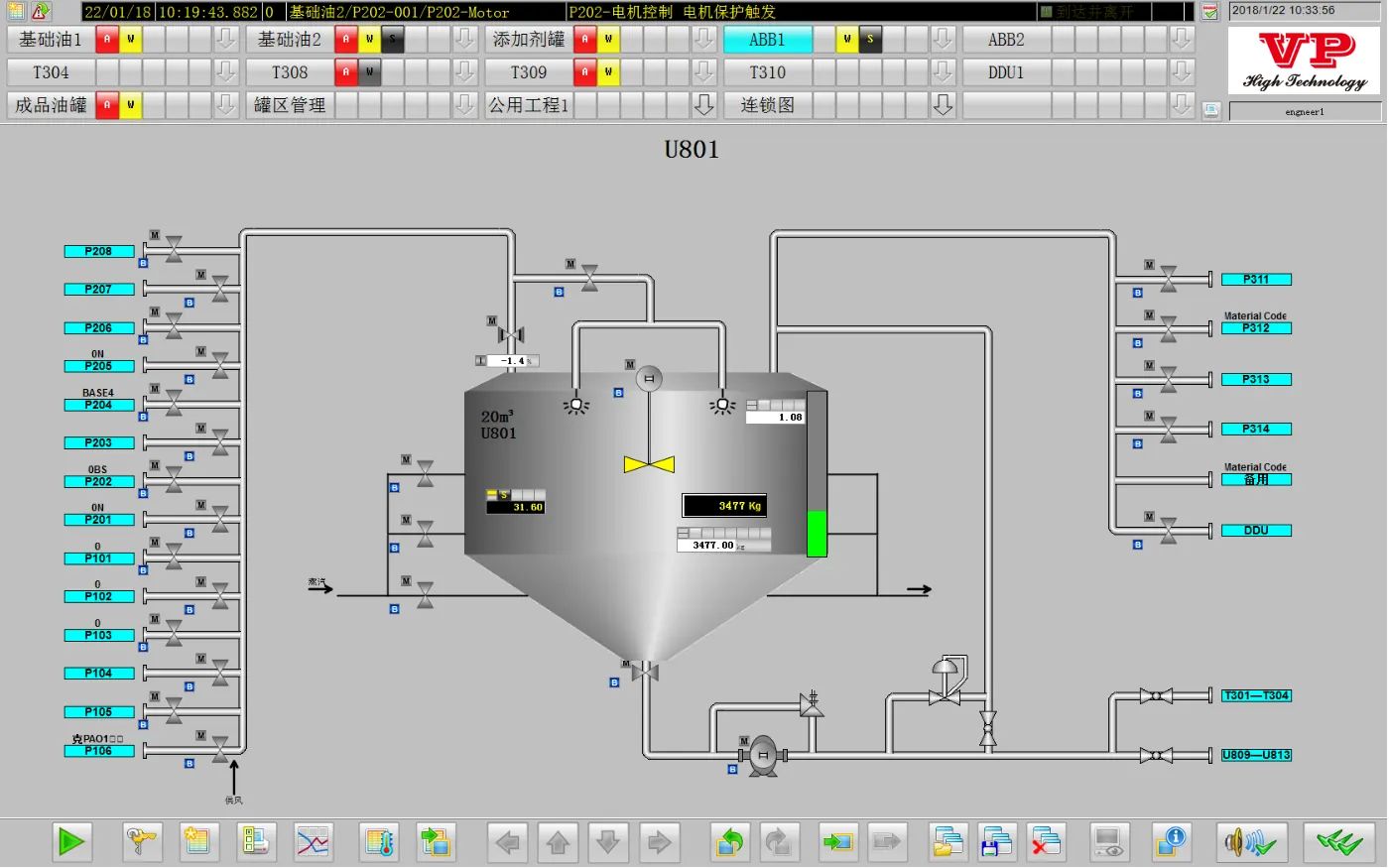

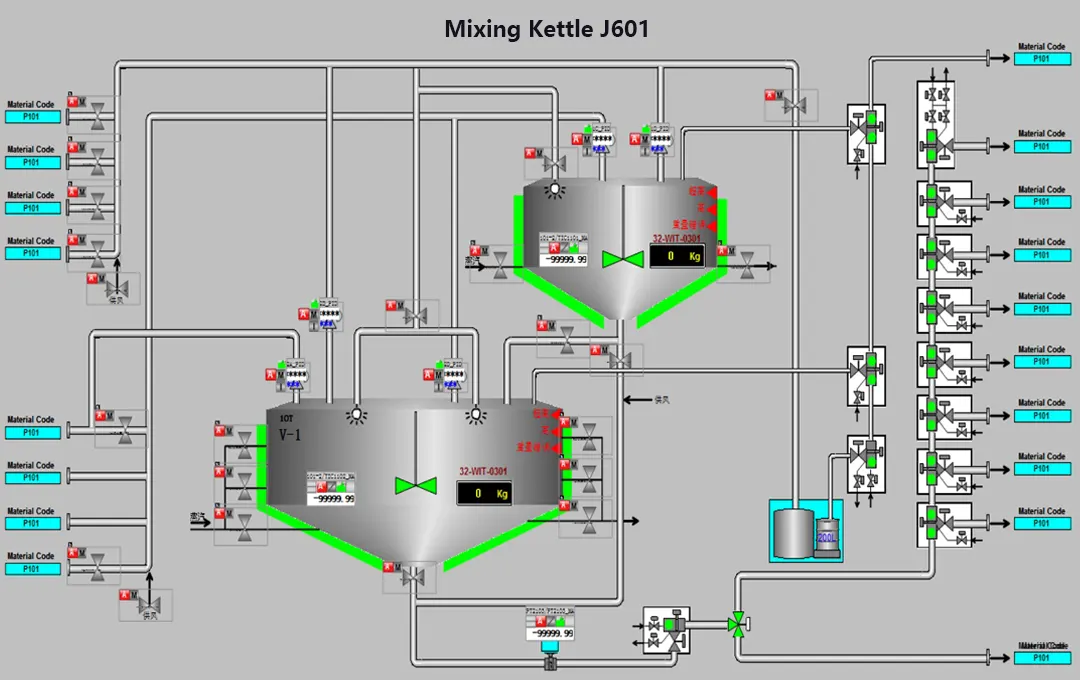

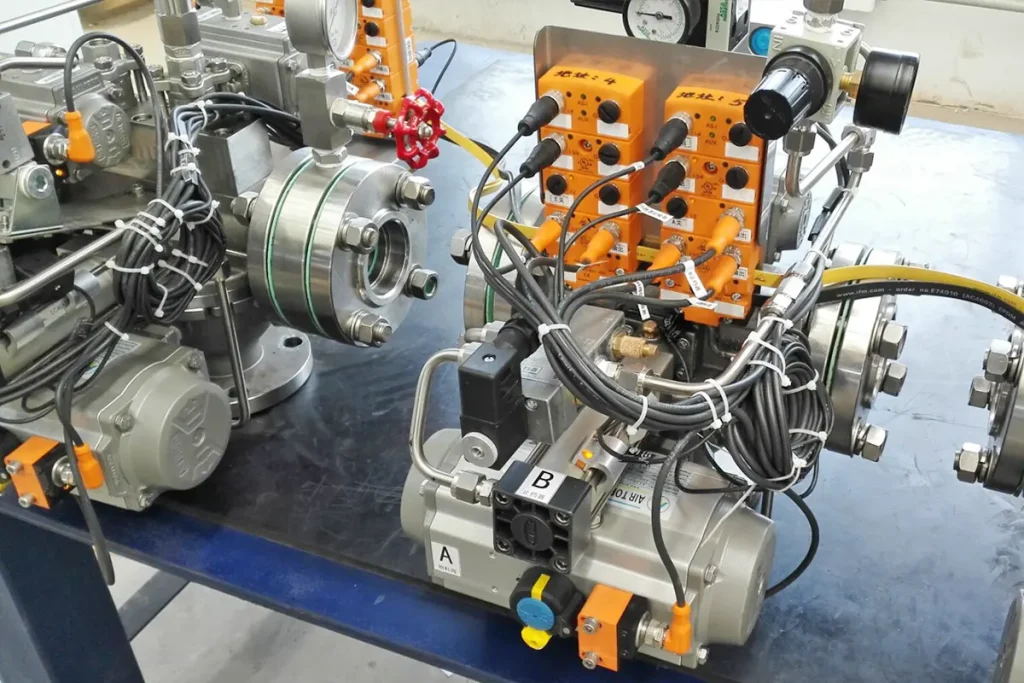

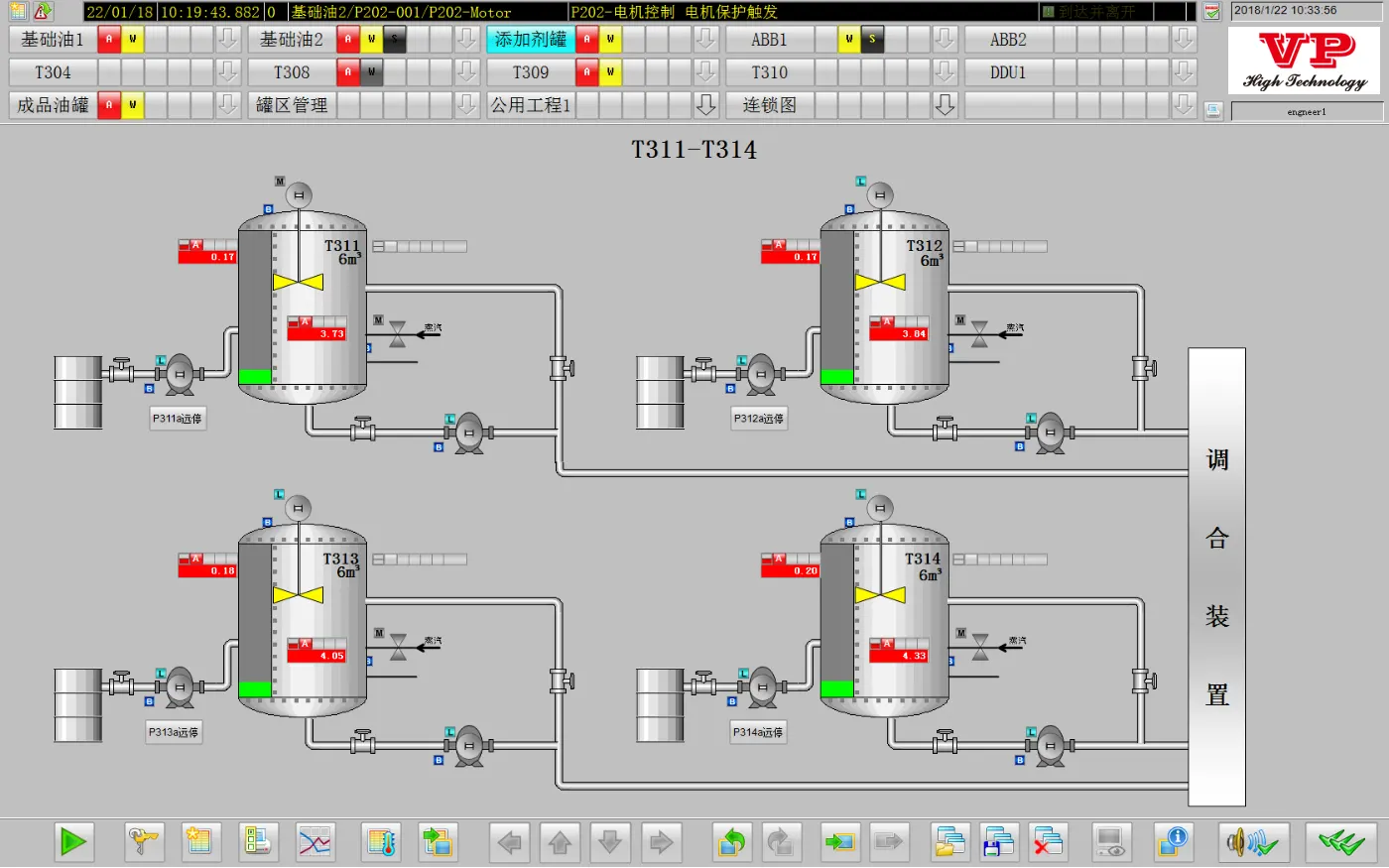

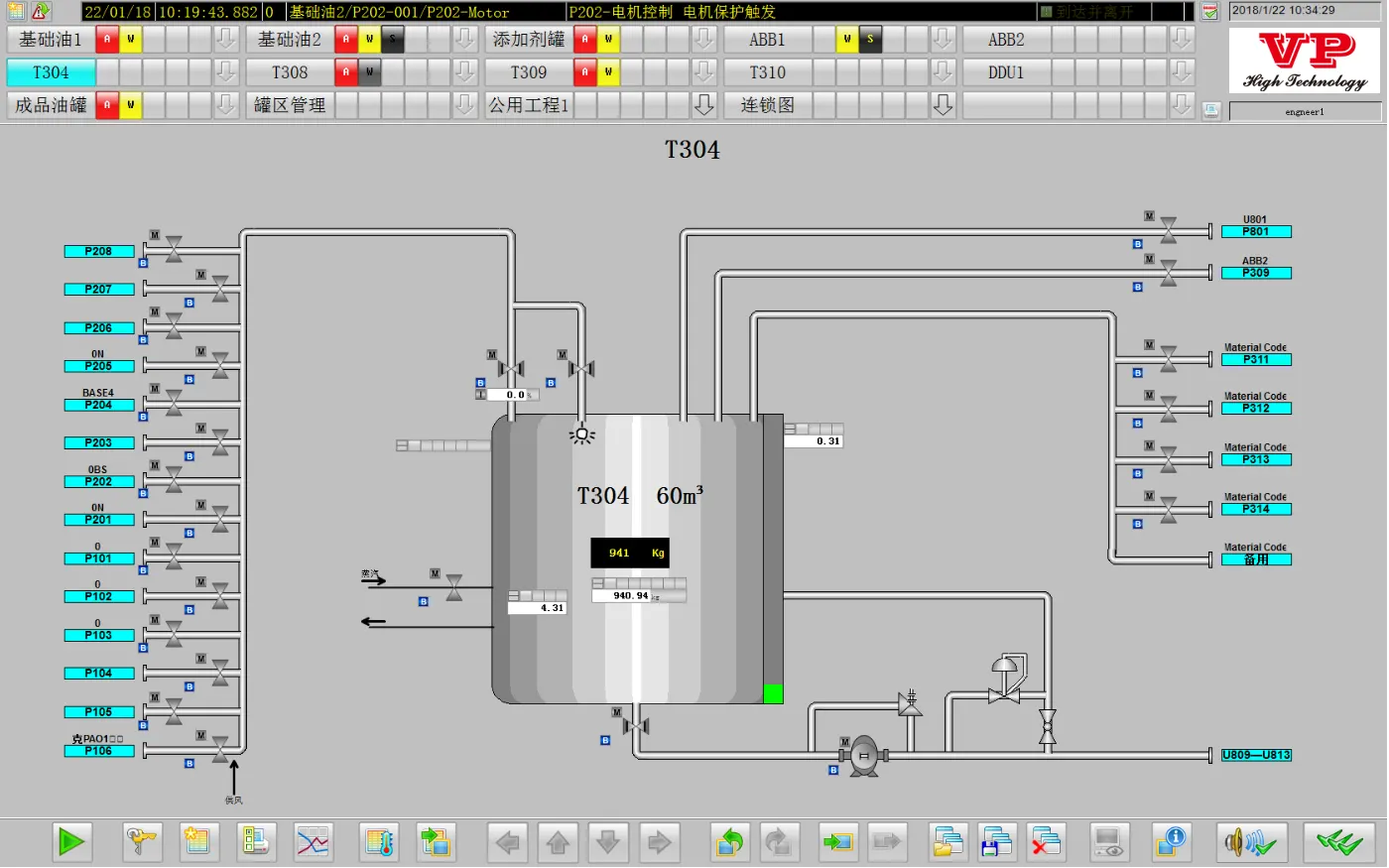

In the pigging system, the equipment must be equipped with a control system (which can also be operated manually). Through real-time monitoring by pressure sensors, it precisely controls the opening and closing of valves, as well as the movement of the Pig inside the pipeline. Typically, to integrate with other systems and achieve full-process control, the pigging system can also operate in coordination with other systems and be centrally monitored by a DCS system. This ensures automated, safe, and efficient pigging operations.

Control System Overview

Pigging Control System is an automated system designed to manage and control pipeline pigging operations. It precisely controls the movement of pigs within the pipeline, ensuring they efficiently and safely complete tasks such as cleaning, inspection, isolation, or product transfer. The system’s core objectives are to reduce waste, enhance overall efficiency, and ensure operator safety.

BJVP System Advantages

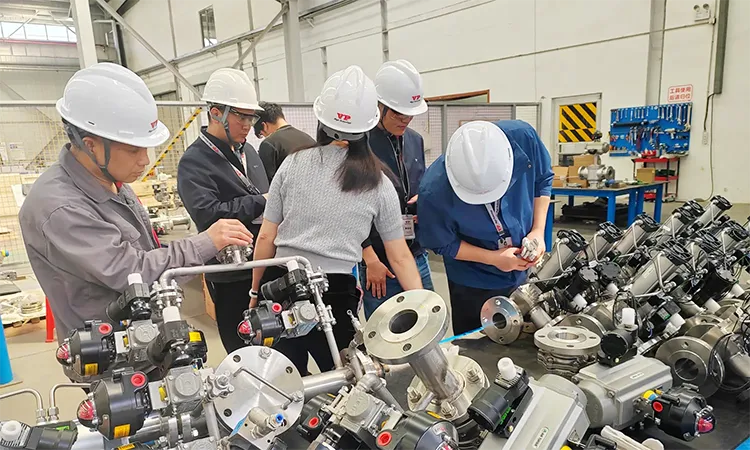

- Automated Operation: Modern pigging control systems utilize specially designed launching and receiving stations to automate feeding, launching, receiving, and cleaning functions. This increases production efficiency and processing speed while eliminating cumbersome manual procedures.

- Enhanced Safety: Predefined operating sequences and self-check functions significantly improve operational safety, reducing hazards caused by human error. Manual operations under pipeline pressure pose substantial risks, which automated control systems effectively mitigate.

- Remote Control & Support: The BJVP Control Center is equipped with a comprehensive DCS (Distributed Control System) software and hardware suite, rigorously tested before shipment. Additionally, we provide clients with remote control services and support, ensuring timely technical assistance during system operation.

Control Operation Modes

The pigging distributed control system utilizes two mutually exclusive operating modes:

- Central Control Room Primary (Field Monitoring): In this mode, the Central Control Room acts as the primary command center, managing and monitoring the entire pigging operation. Real-time field data from sensors and monitoring devices feeds back to the Central Control Room, enabling operators to precisely control pigging operations.

- Field Control (Central Control Room Monitoring): When on-site operation is required under special circumstances, the system switches to Field Control mode. Field personnel gain direct control of pigging equipment, while the Central Control Room monitors operations to ensure compliance with safety protocols.

Control Permission Management

Through a permission interlock protocol, the system ensures exclusive single-point control authorization. This mechanism effectively prevents signal conflicts and safety hazards caused by dual control operations, guaranteeing smooth pigging operations.

BJVP Pigging Distributed Control System, with their advantages of automated operation, enhanced safety, and remote control capabilities, provide more efficient and safer solutions for industrial pigging operations. They replace the complexity and dangers of traditional manual methods while utilizing advanced control technology to boost the efficiency and reliability of the entire pigging process.