A pigging system efficiently recovers product residue and cleans pipelines through the coordinated operation of its core components. Below are the essential parts and their functions:

1. Pig (Pigging Ball)

Function: The primary actuator that physically contacts the pipe wall to push out residual product, remove deposits, or separate media.

Types:

- Solid Spheres (Silicone/Polyurethane): Hygienic-grade, easy to clean.

- Multi-component Pigs (with scrapers/brushes): For viscous/solid residues in industrial applications.

- Smart Pigs (with sensors): Detect pipe deformations, corrosion, or temperature (advanced use).

Material Selection:

- Hygienic: FDA-grade silicone/polyurethane, high-polish, non-toxic.

- Industrial: Wear-resistant polyurethane, acid-proof rubber, or composites for high-pressure/corrosive environments.

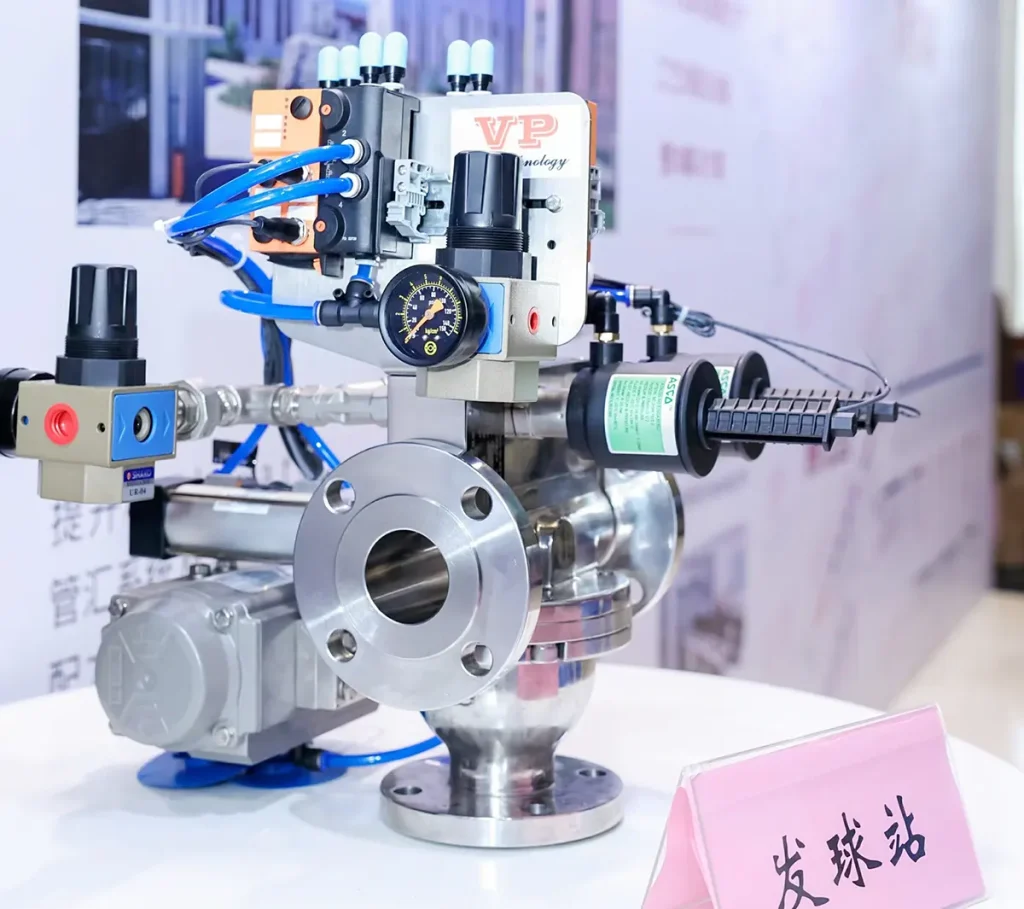

2. Launching Station

Function: The entry point for deploying pigs, typically at the pipeline start.

Components:

- Pressure vessel (barrel)

- Quick-opening closure (Tri-Clamp for hygienic, flanged for industrial)

- Medium injection valve (gas/liquid to propel the pig)

- Pressure/position sensors

Example Models: WPE ASHLDV (hygienic), standard industrial launchers.

3. Receiving Station

Function: Captures and retrieves pigs at the pipeline end.

Design Features:

- Buffer mechanism (reduces pig impact)

- Discharge valve (removes residual media/product)

- Sight glass (hygienic-grade for easy inspection)

Example Models: WPE ASRLDV (hygienic), industrial receivers.

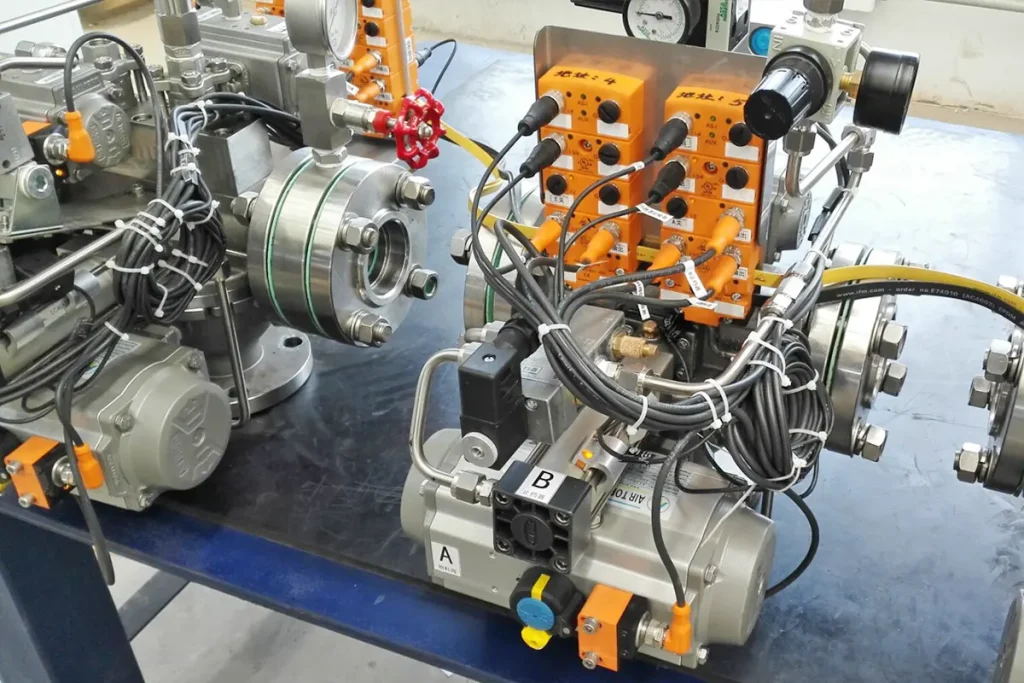

4. Distributed Control System

Function: Provides driving force (gas/liquid) to move pigs.

Key Elements:

- Compressed gas/liquid source (N₂, air, water, or process fluid)

- Precision control valves (regulate flow/pressure for smooth operation)

- Pressure gauges & sensors (real-time monitoring)

5. Pipeline Connections & Valves

Hygienic-Grade:

- Tri-Clamp fittings: Quick disassembly, dead-space-free, 3-A/SMS compliant.

- Sanitary valves (butterfly/ball): Polished internals, CIP/SIP compatible.

Industrial-Grade:

- Welded/flanged connections: High-pressure (>Class 600) and high-temperature (>200°C) resistant.

- Pig valves/diverters: Guide pigs to avoid branch pipelines.

6. Auxiliary Equipment

- Pig Loader/Unloader: Safely installs/removes pigs without contamination (hygienic) or high-pressure risks (industrial).

- Intermediate Station (e.g., ASILDV): Enables pigging in long/complex pipelines.

- 3-Way Diverter (e.g., 3W): Routes pigs in multi-branch pipelines.

System Integration Key Parameters

| Component | Hygienic-Grade Specs | Industrial-Grade Specs |

|---|---|---|

| Pipe Size | 1.5″ – 8″ (high precision) | 2″ – 48″+ (standard) |

| Connection Type | Tri-Clamp | Welded/ANSI Flange |

| Valve Type | Sanitary Butterfly + CIP Port | Pig Valve + High-Pressure Gate |

| Pig Material | FDA Silicone/Polished | Abrasion-Resistant PU/NBR |

| Pressure Rating | Up to 10 bar | Up to 400 bar |

Why Are These Components Indispensable?

- Pig: Directly affects cleaning/recovery efficiency.

- Launch/Receive Stations: Ensure safe pig entry/exit.

- Propulsion System: Provides consistent driving force.

- Valves & Piping: Maintain system integrity (leak-proof in industrial, contamination-free in hygienic).

- Auxiliary Stations: Enable complex pipeline configurations (long-distance, multi-branch).

Example Applications:

- Dairy Plant (Hygienic): A pig launches from an ASHLDV station, propelled by N₂ through Tri-Clamp piping, recovering 99.6% yogurt, and is captured in an ASRLDV station before automated CIP cleaning.

- Chemical Plant (Industrial): A multi-component pig clears resin residue at 50 bar/80°C, guided by pig valves to the receiver.

Understanding these core components and their synergy is critical for optimizing pigging system design, maximizing recovery rates, and reducing operational costs.

Articles Related

-

VP Pigging System: Efficiency Pipeline Cleaning & Recovery

The pigging system (also known as ball-pigging system or product recovery system) is specialized equi...

-

What Are the Key Benefits of Pigging Systems?

A pigging system utilizes specialized pipeline pigs (cleaning pigs) to clean, maintain, and recover ...

-

3-Way Distribution Valve: Precise Flow Diversion & Efficient Pigging

The 3-Way Distribution Valve is specifically designed for complex pigging systems. It allows pig pass...