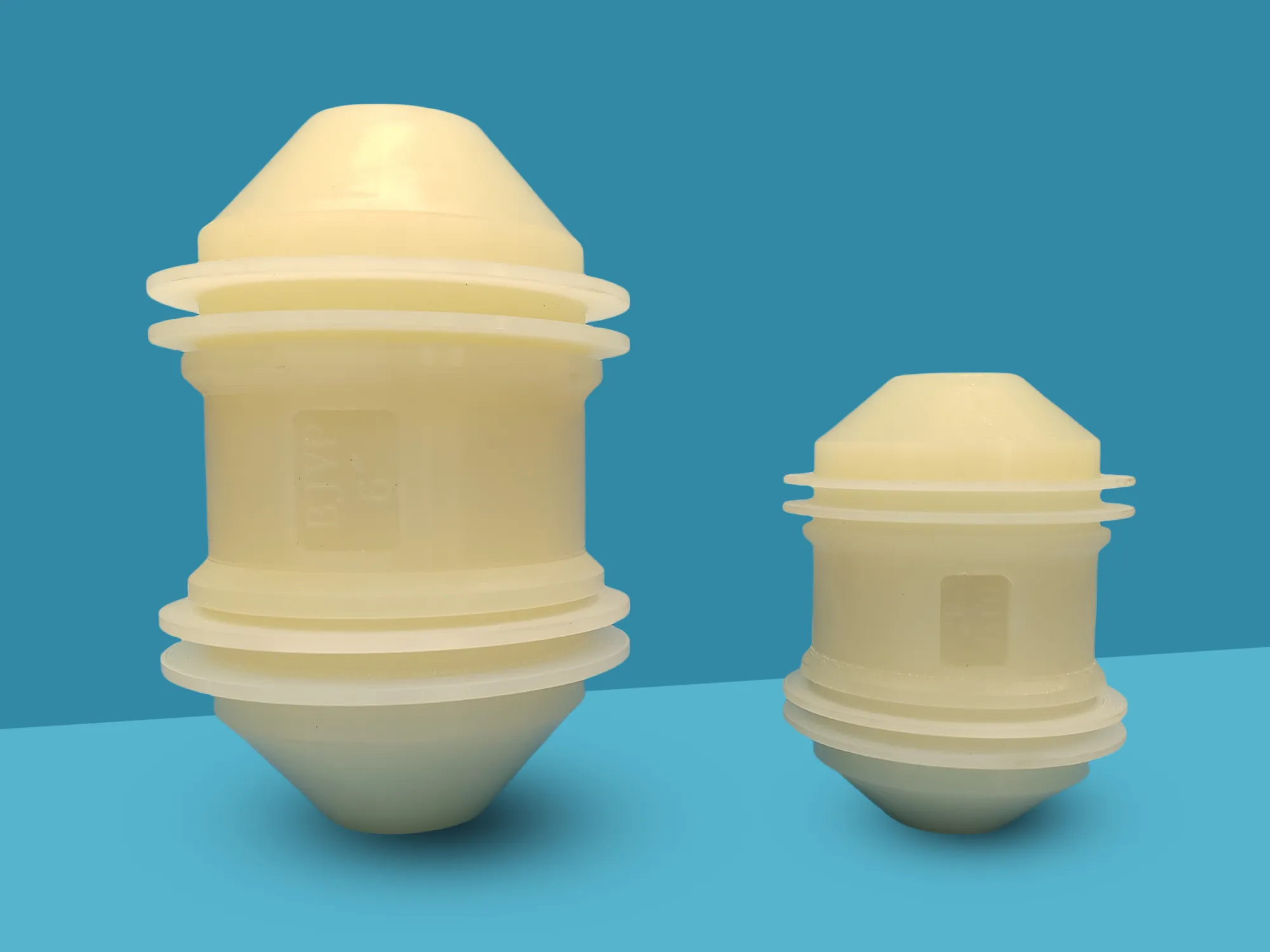

Pigging balls (pigs) are near-spherical pipeline cleaning devices made of elastic materials (e.g., specialty rubber, polyurethane) with a diameter slightly larger than the pipeline’s inner diameter (2%~10% interference fit) to ensure tight wall contact. Driven by pipeline media (gas or liquid), they travel through pipelines to perform cleaning, product recovery, and other functions.

1. Material Selection

Pigging balls are typically made of rubber or polyurethane, with common shapes including cylindrical and disc designs for varying operational needs. Different materials exhibit distinct properties:

- Modified polyurethane balances flexibility and wear resistance, ideal for long-term operations.

- Fluorocarbon rubber (FFKM) offers superior corrosion resistance while maintaining wear resistance but at a higher cost.

- EPDM rubber provides cost efficiency with slightly lower wear resistance.

Selection criteria:

- For highly corrosive media: Fluorocarbon rubber pigs.

- For low-corrosion, cost-sensitive applications: EPDM rubber pigs.

VP Company’s advanced polyurethane technology delivers multi-material pigs for diverse conditions:

| Material | Properties | Applications |

|---|---|---|

| Polyurethane (PU) | High elasticity, wear/tear resistant | Oil/gas, chemical pipelines |

| Fluorocarbon (FFKM) | High-temp (≤200°C), chemical-proof | Strong acid/alkali pipelines |

| Silicone rubber | Food-grade, cryogenic (-60°C) | Food/pharmaceutical pipelines |

Surface treatment technology: The outer wall of the sphere is treated with special textures or coatings, which can efficiently scrape off residues on the pipe wall.

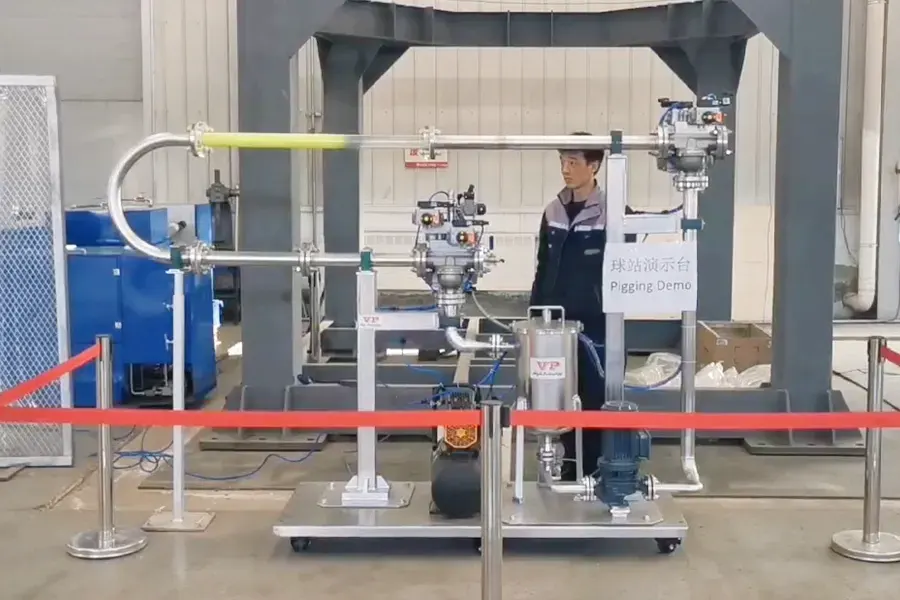

2. Drive System

- Drive media: Compressed air/nitrogen (prevents oxidation).

- Pressure control: Dynamically adjusted (0.1-10 MPa) based on pipeline length/media viscosity.

- Real-time tracking: Sensors monitor pig position/speed for closed-loop control.

- Automation: PLC-integrated operation minimizes manual input.

3. Structural Design

| Type | Design | Advantage |

|---|---|---|

| Industrial pigs | Modular, detachable | Easy maintenance |

| Sanitary pigs | Seamless, one-piece | Zero contamination risk |

4. Selection Principles

- Media compatibility: Fluorocarbon for corrosive media; silicone for food-grade pipelines.

- Temperature: Use high-temp specialty rubber above 120°C.

5. Key Industry Applications

| Industry | Recommend | Drive Media |

|---|---|---|

| Oil & gas | Modified polyurethane | Nitrogen (explosion-proof) |

| Pharmaceuticals | Fluorocarbon/FFKM | Compressed air |

| Food & beverage | Seamless silicone pigs | Sterile compressed air |

6. Technology Trends

- Eco-materials: Biodegradable polyurethane in development.

- Digital twins: Predictive path/wear modeling using pipeline data.

VP’s innovation: Proprietary modified polyurethane formulations outperform standard PU in heat resistance.

Optimal pigging performance relies on synergy between material science, structural design, and smart control. VP offers customized solutions for pipeline self-cleaning and autonomous operation.

Articles Related

-

2025 China International Coatings Exhibition, Invitation from BJVP(Nov 25–27)

Dear Customers and Partners, Greetings! We sincerely invite you to visit the 2025 China International...

-

VP Pigging System Use for Recovery of Product

What is BJVP Pigging System Used for Recovery? At the end of pumping a product through a pipeline, re...

-

BJVP Unveils Pipeline Cleaning Pigging Tech at 2025 Coatings Smart Manufacturing Conference

From November 23 to 25, 2025, the China International Coatings Smart Manufacturing Industry Chain Dev...