Pig stations are essential components of pigging systems, enabling automated launching and receiving of pigs. They are key to efficient and automated pipeline cleaning and inspection. Here are the primary types:

1. Launch Stations & Receive Stations

The core units for automated pig launching (into the pipeline) and receiving (out of the pipeline). Precise pressure and process control ensure smooth pig operation for cleaning or inspection tasks.

2. Intermediate Stations

Allow pigs to make temporary stops at specific pipeline points. Enables focused cleaning or inspection of targeted sections, increasing operational flexibility and precision.

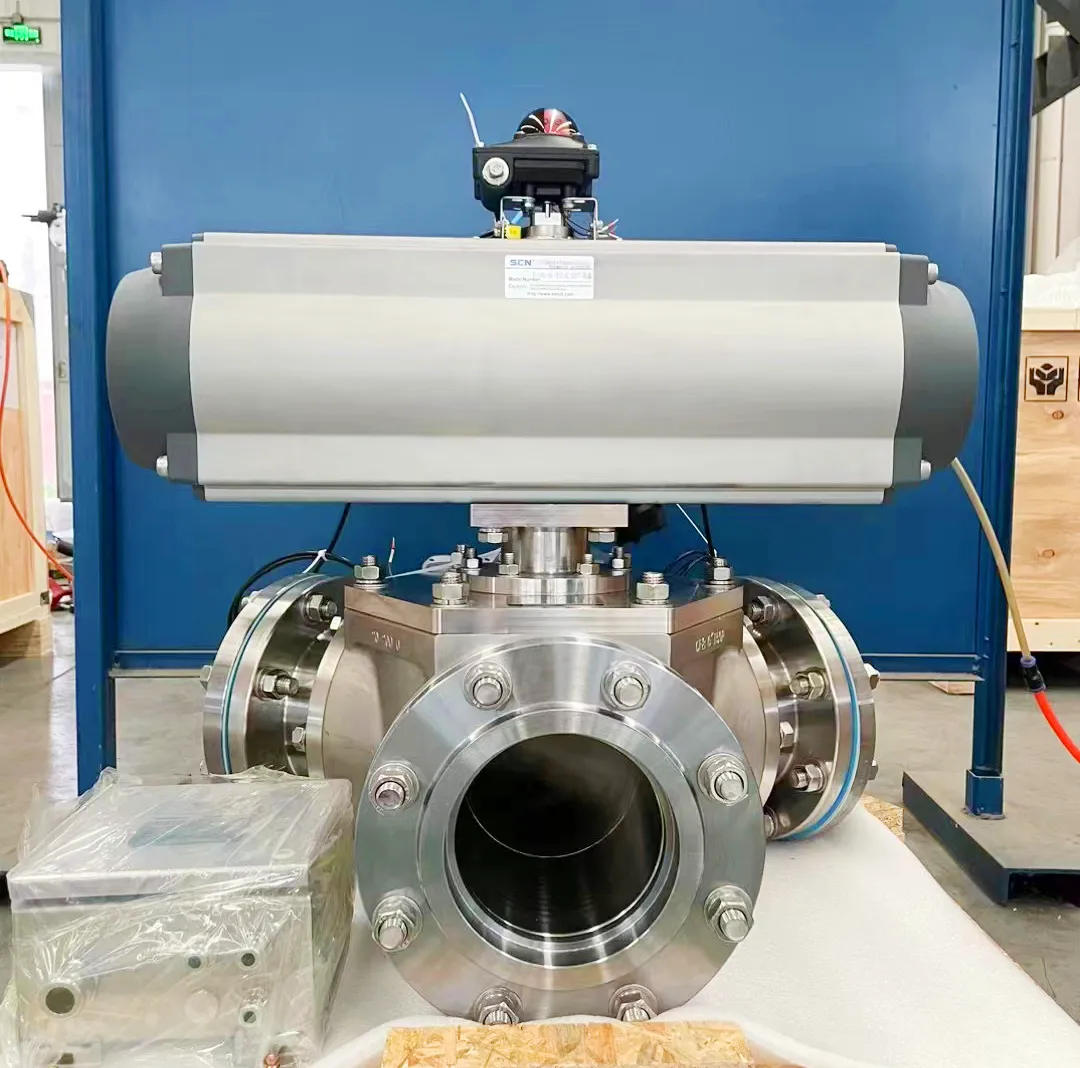

3. T-Type Diversion Valves

Specialized valves directing pigs into different pipeline branches. Facilitates multi-path pigging operations, optimizing maintenance across complex pipeline networks.

4. Three-Way Diverter Stations

Enable reliable switching of the pig’s path between different pipelines or branches. Ensures pigs enter the correct section, preventing operational delays or failures.

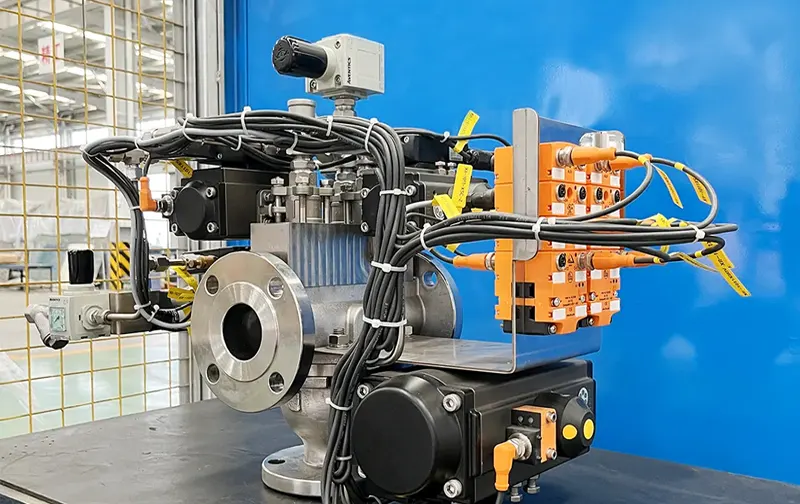

5. Four-Way Transfer Stations

Complex units connecting two separate pipeline sections. Directs pigs between distinct pipeline networks, enabling cross-network pigging and enhancing overall system capability.

VP Pigging System Advantage: Our integrated pigging stations automate pig launching, receiving, and path diversion, meeting diverse industrial demands for efficient and reliable pipeline operation.

Articles Related

-

Drum Decanting Unit, ABB Blending System & Pigging System Integrated Solution

BJVP has successfully delivered a custom Drum Decanting Unit(DDU), Automated Batch Blending System(AB...

-

Pig Launcher (Launcher Station), Core Component of Pigging Systems

In pigging systems, the Pig Launcher (Launcher Station) plays the critical role of the “startin...

-

Pigging Distributed Control System: Pipeline Safety & Efficiency

In the pigging system, the equipment must be equipped with a control system (which can also be operat...