On September 18, the “2025 Green Coatings Development Forum & the 23rd Waterborne Technology Annual Conference” was grandly held in Chengdu. The two-day event attracted over 500 representatives from upstream and downstream enterprises, research institutes, and industry associations. The forum focused on key topics such as green coatings R&D, eco-friendly coating processes, low-carbon technologies, policy and standards optimization, and downstream application innovations.

A Technology Feast Driving Industry Innovation

The forum featured 18 keynote presentations by experts and scholars from leading global companies and research institutes. They shared industry insights, the latest scientific achievements, case studies, and future outlooks, offering valuable perspectives for the innovation and sustainable development of the green coatings industry.

Mr. Gou Jingsheng, General Manager of BJVP, and Ms. Sabrina, Technical Director, were invited to attend. During the event, Ms. Sun delivered a keynote speech on “Pigging Technology for Material Recovery in Coatings Pipelines and Drum Decanting Unit (DDU) Technology for Automatic Drum Extraction.” She highlighted the practical applications and unique advantages of VP’s Pigging Systems and DDU in the coatings industry. The professional insights and cutting-edge results received strong recognition and positive feedback from participants.

Fully Automated & Unmanned Production Solutions for the Coatings Industry

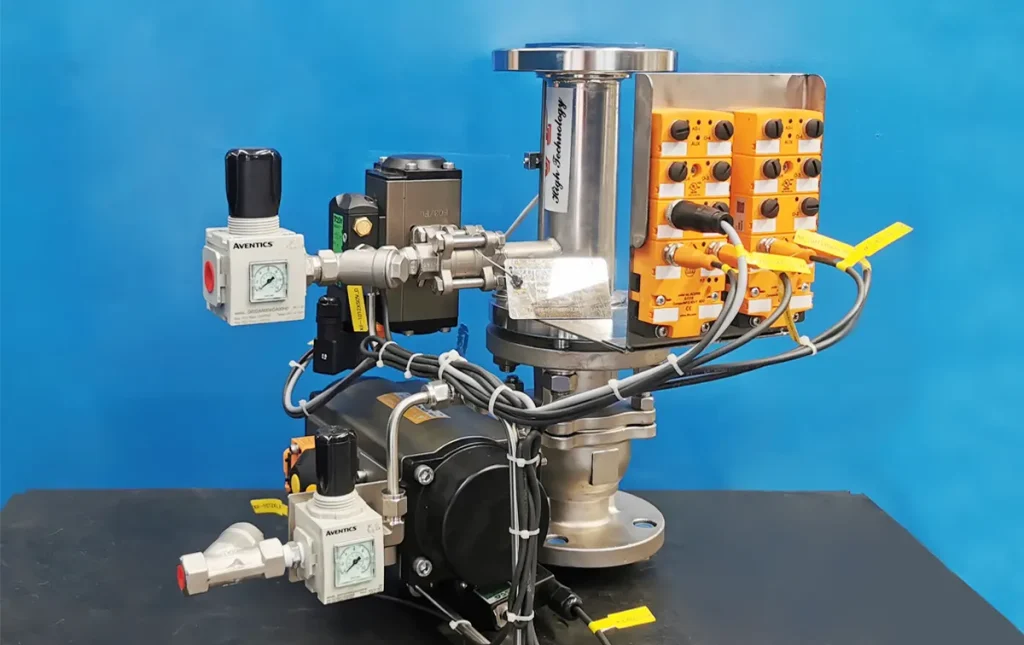

- Pipeline Pigging Cleaning System

- Manifold Pigging System

- DDU Automatic Drum Decanting System

- ABB Automatic Batch Blending System

- Batch Automatic Formulation Production System

- 150BS Pumps for High-Viscosity Materials

Visitors from the coatings sector showed strong interest in BJVP’s advanced automation technologies and expressed willingness for deeper cooperation. These innovations are driving process upgrades and helping the coatings industry enter a new stage of development.

This participation not only showcased VP’s technological strengths in coating processes and equipment but also reaffirmed the company’s commitment to green, low-carbon concepts and sustainable industry development. Moving forward, BJVP will continue to focus on R&D, delivering more efficient and eco-friendly solutions to create greater value for the global coatings and lubricants industries.

VP Product Applications in Coatings

VP’s Pigging Systems can clean pipelines and recover residual materials within one minute, achieving a recovery rate of up to 99.9%. Especially suitable for fast color changes and material recovery in industrial coating pipelines, effectively preventing cross-contamination, meeting eco-clean requirements for waterborne coatings, improving efficiency, and reducing waste.

The DDU is designed to automatically and accurately decant materials from 200L drums or IBC totes into blending tanks under program control. The system includes: decanting gun with lifting mechanism, weighing platform, drum rollers, insulated cleaning oil tank, decanting pump, automated valves, monitoring instruments, and operator interface.

VP’s Automated Drum Decanting Unit offers multiple advantages: 1) Eliminates manual handling, reducing HSE risks; 2) Fully empties a 200L drum in under 2 minutes; 3) Accurate and automatic dosing; 4) Neat and leak-free operations, avoiding environmental pollution; 5) Automatic cleaning reduces waste and cross-contamination; 6) Minimizes on-site labor and exposure to hazardous vapors; 7) Integrates with MES for fully unmanned “dark factory” automation.

BJVP – Global Leader in Fluid Transfer & Process Engineering

Founded in 1996, BJVP specializes in automated Pigging Systems and Drum Decanting Units. With decades of expertise and innovation, BJVP has independently developed core technologies in fluid transfer and process control, delivering fully automated blending processes and equipment tailored to modern production needs. Proven through years of market application, VP’s solutions are recognized for their quality and reliability, securing a leading position in the industry.

Main Products: Pigging Systems, Drum Decanting Units, Pigging Manifold Systems, ABB Automatic Batch Blending Systems, SMB Synchronous Metering Blending Systems, ILB In-Line Blending Systems, Lubricant Batch Management Systems, DCF Systems, PCS & DCS Lubricant Blending Control Systems (VPBLEND®), VI Improver Gel Systems, and high-viscosity additive solutions including thickening agents and heavy-duty gear pumps.

Articles Related

-

Pig Receiver Station: Receiving, Storage, Reloading of Pigs

In pigging systems, the Pig Receiver (Receiver Station) plays a critical end-point role, serving as c...

-

Material Selection and Working Principle of Pipeline Pigs

Pipeline pigs are specialized projectiles used in pigging systems to evacuate or recover residual med...

-

2025 China Coatings Industry Information Conference: VP Pigging System Drives Innovation

The 2025 China Coatings Industry Information Conference was successfully held from November 5–7 in Ha...