Benefits of Using VP Pigging System

High efficiency, reliable performance, and user-friendly operation

-

Maximize Recovery

Achieve up to 99.9% recovery rate, significantly reducing product waste reducing product waste.

-

High ROI

Cost savings allow quick return on investment, with long-term profit growth.

-

Sustainability

Reduce water usage, chemical consumption, and disposal costs, delivering significant environmental benefits.

-

Wide Applicability

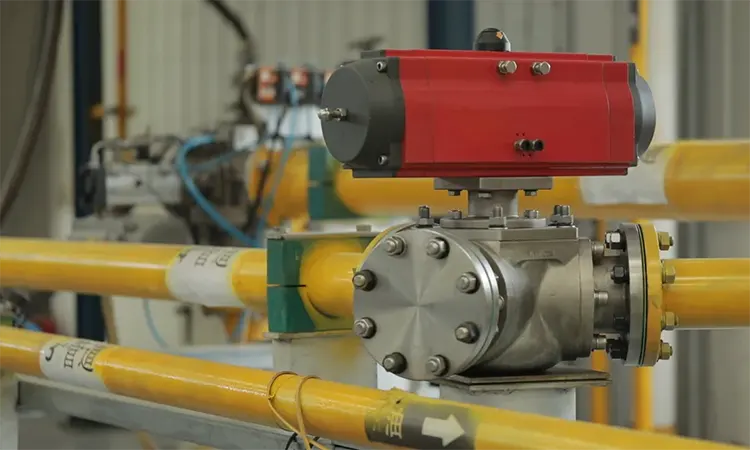

Suitable for various liquids (viscous, thick, solid, etc.) in pipeline cleaning.

-

Minimize Cross-Contamination

Lower the risk of product contamination and enhance pipeline flexibility.

-

Increase Pipeline Utilization

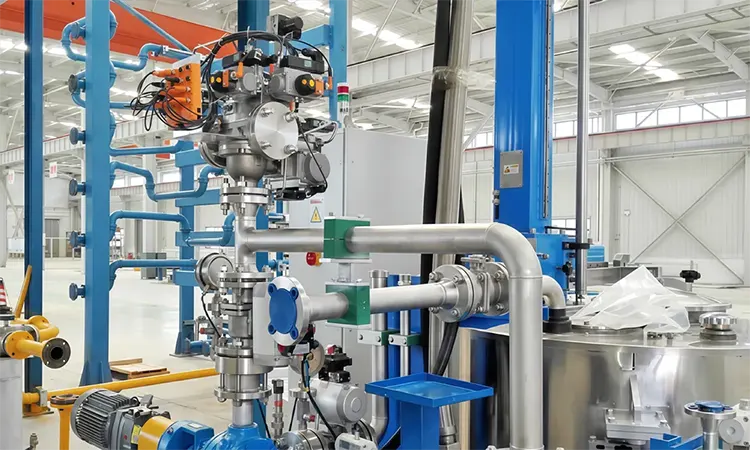

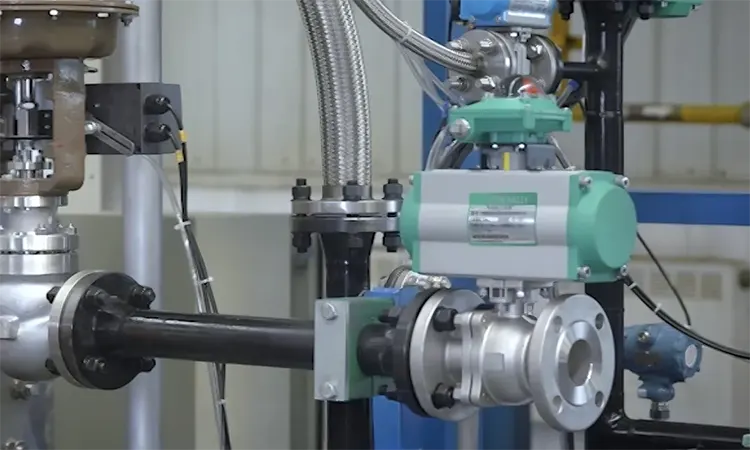

Its efficient cleaning function allows the same pipeline to quickly switch between different product batches, significantly enhancing pipeline utilization while greatly reducing the consumption of cleaning fluids and water.

Why Choose VP Pigging System?

With 30 years of global pigging expertise across multiple industries, we are a leader in designing, manufacturing, and supplying automated lubricant blending solutions. We've delivered numerous complex, large-scale pigging projects worldwide, backed by comprehensive support from engineering to maintenance. Our advanced technology and deep pipeline cleaning experience ensure optimal system efficiency, safety, and cost-effectiveness. Our Service >>

-

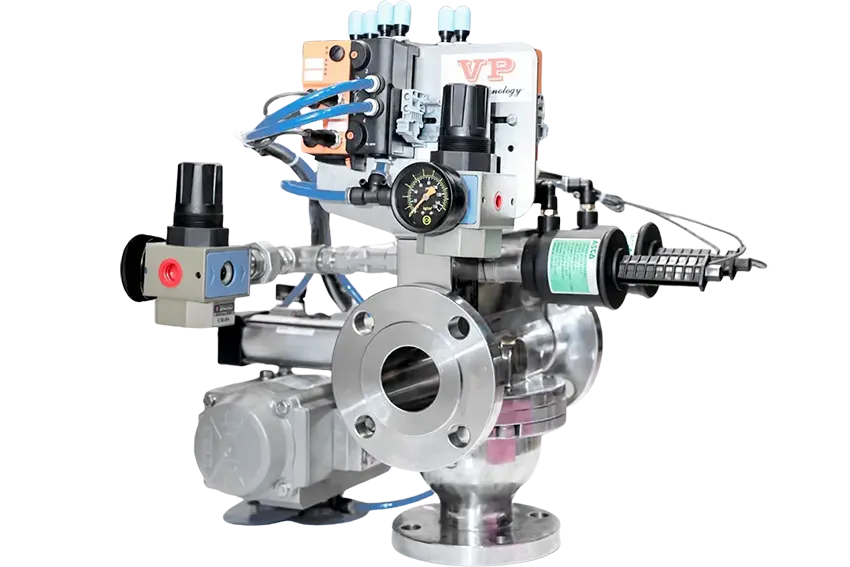

Custom Pigging System

-

Technology Innovation

-

Strong Production Capacity

-

Efficiency and Safety

-

Installation and Training

-

Reliable After-sales

About BJVP

We are an experienced pigging system manufacturer, established in 1996. We provide design and equipment manufacturing engineering services for manual pigging systems, automated pigging systems, hygienic pigging systems, and sterile pigging systems to a wide range of industries.

Our products are extensively utilized in industries including lubricants, additives, food and beverage, coatings, pharmaceuticals, and any application that involves the pumping and conveyance of liquid products through pipelines.

-

1996+

Factory Founded

-

88+

Technical Personnel

-

1000+

Partner Customers

-

2000+

Liquid Transfer Solutions

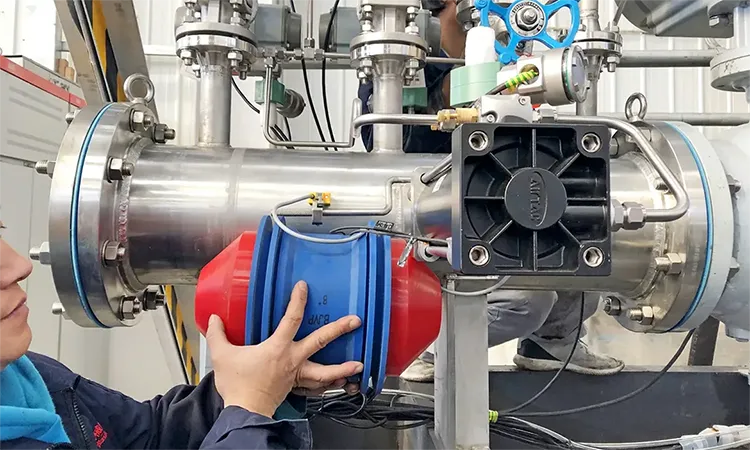

VP High-Quality Pigging Systems & Product Recovery Solutions

VP is committed to the development of high-quality pigging systems and continuously drives innovation and advancement in pigging technology. We design and manufacture cost-effective, easy-to-integrate pigging products to meet the diverse needs of our customers. More Gallery >>

Customer Service Distribution

We are proud to provide efficient, eco-friendly, and cost-effective pipeline CIP cleaning systems and services to global clients across various industries.

Our Partners

-

BJVP Harvests at 2025 CHINACOAT: Pioneering Industry Change with Pigging Technology

From November 25 to 27, 2025, the global coatings industry event, the “China International Coatings Exhibition (CHINACOAT)”, was grandly h...

Read More -

Paint and Coating Pipeline Residue and Color Contamination? VP Pigging System with Nearly 100% Cleaning Efficiency

A Pigging System is a technology that uses a specialized elastic scraper called a “Pig” to remove, push, and recover residual media inside...

Read More -

Types of Pig Stations in Pigging Systems

Pig stations are essential components of pigging systems, enabling automated launching and receiving of pigs. They are key to efficient and automated ...

Read More