We've more than 30 years of industry experience in the field of pigging systems, and have accumulated extensive project experience and significant scientific research achievements over the years.

We've participated in formulating multiple pigging system industry standards. Our specialists have pioneered advancements and practical implementations in pipeline pigging technology.

VP Pigging System

30 Years' Expertise in liquid transfer and pigging system

How Pigging Systems Work in Liquid Pipelines?

Why Pigging Systems? At the end of a product transfer, some material inevitably remains in the pipeline, causing waste and economic loss. Traditional methods, such as flushing with water or cleaning agents, are inefficient, incomplete, time- and labor-intensive, and generate large volumes of wastewater and pollutants.

A pigging system is designed for pipeline cleaning, maintenance, and product recovery. It works by propelling a pig—slightly larger than the pipeline’s inner diameter—through the line using compressed air (or nitrogen) or cleaning liquids. The pig effectively scrapes the inner walls, pushing residual product to a recovery container, enabling thorough cleaning while maximizing product recovery and minimizing waste. The pig’s outer layer is made from elastic, wear-resistant materials such as polyurethane or special rubber, and often contains built-in magnets for position tracking via magnetic sensors.

Contact VP

VP Pigging System of Double Pigs Demo

Benefits of Using VP Pigging

-

Cost reduction and profitability improvement

By recovering the remaining valuable product in the pipeline, the BJVP pigging system directly reduces material waste, lowers production costs, and thus improves the profitability of the enterprise. Companies are able to use raw materials more efficiently and reduce additional procurement costs due to lost products.

-

Prevent Liquid Cross-Contamination

When transferring different media, the remaining liquid can be swept into any designated branch pipeline, thereby avoiding cross-contamination.

-

Maximized Product Recovery

Highly efficient residue removal minimizes product waste and ensures 99.9% material recovery rate.

-

Flexible Control

When the liquid transfers through the main pipe, the remaining liquids can be swept to any designated branch pipe so that the cross contamination will be avoided, adaptation to diverse process requirements.

-

High Automation

Easy to operate, simple to manage, eliminating costly human mistakes.

-

Space-Saving Infrastructure

Significantly reduces pipeline infrastructure requirements and saves valuable floor space - up to 40% less piping compared to traditional systems.

-

Environmental benefits and sustainable development

The pigging system reduces the use of wastewater and other cleaning agents generated by flushing pipes, reducing environmental pollution, and achieve sustainable development.

Pigging Solutions for Various Fields

Pigging systems are Widely used in a variety of industries such as:

Helping businesses reduce waste and increase profitability.

INDUSTRIAL PIGGING & SANITARY PIGGING

Industrial Pigging

Recover product, efficiently remove residue, and withstand demanding conditions including high temperatures, high pressure, corrosive media, and frequent operations. Pipelines typically utilize welded or flanged connections for sealing performance, primarily serving the petrochemical, lubricating oils industry.

Sanitary Pigging

Prioritize thorough cleaning, zero residue, and contamination-free processes. After pigging, pipelines are flushed with water or cleaning agents. For rapid disassembly and sanitation, hygienic tri-clamp (Tri-Clover) connections are used, making them ideal for food, pharmaceutical, and cosmetic industries.

VP Pigging Demo

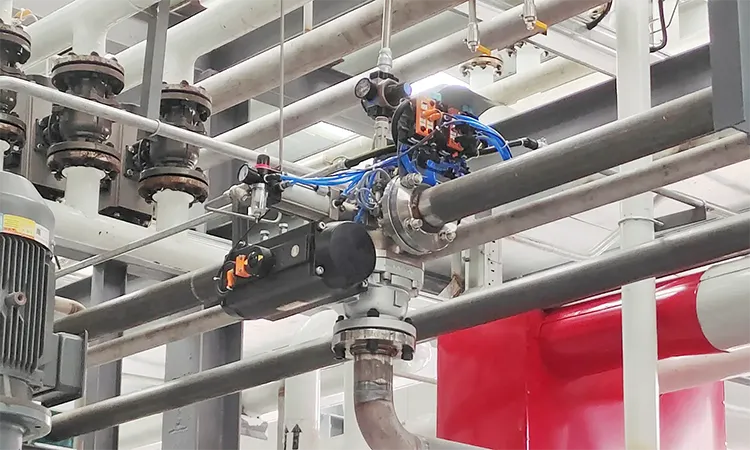

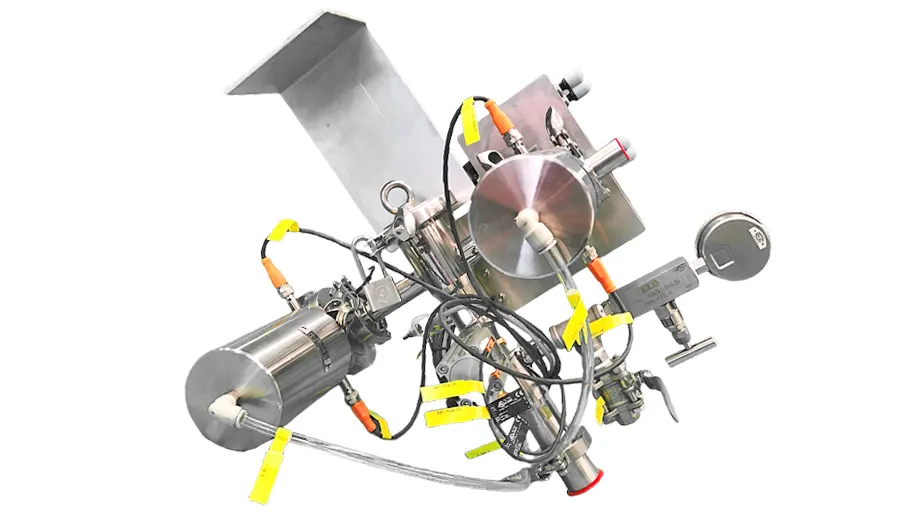

Main Equipment in Pigging System Includes: Launching/Receiving Stations(Core Components), Intermediate Pigging Stations, Cleaning Pigs (various materials, Such as Foam Pigs), Piggable Pipeline Sections, Reinforced Pipe Sleeves, Pig Tracking Sensors, Industrial-Grade Communication Cabling, PLC-Based Control System, Pig Loader/Unloader(Optional) and Control Systems.

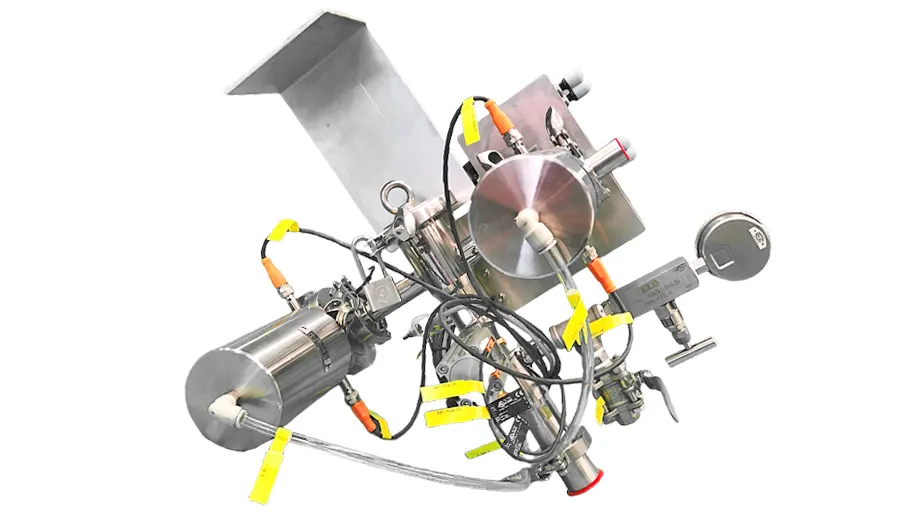

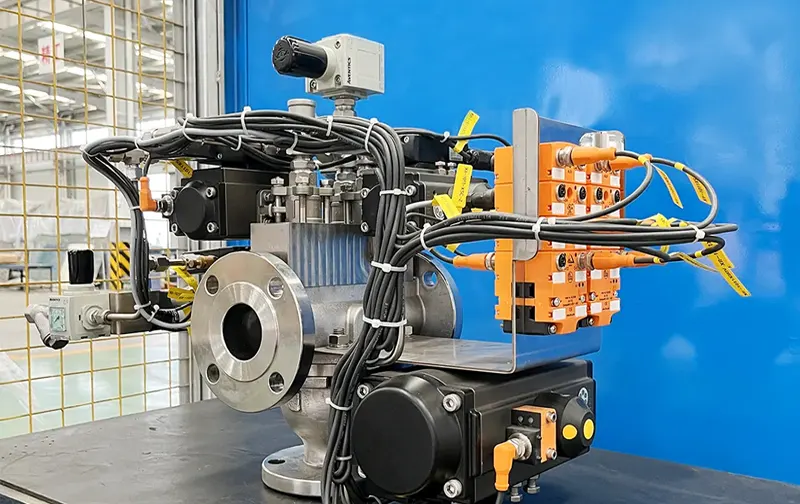

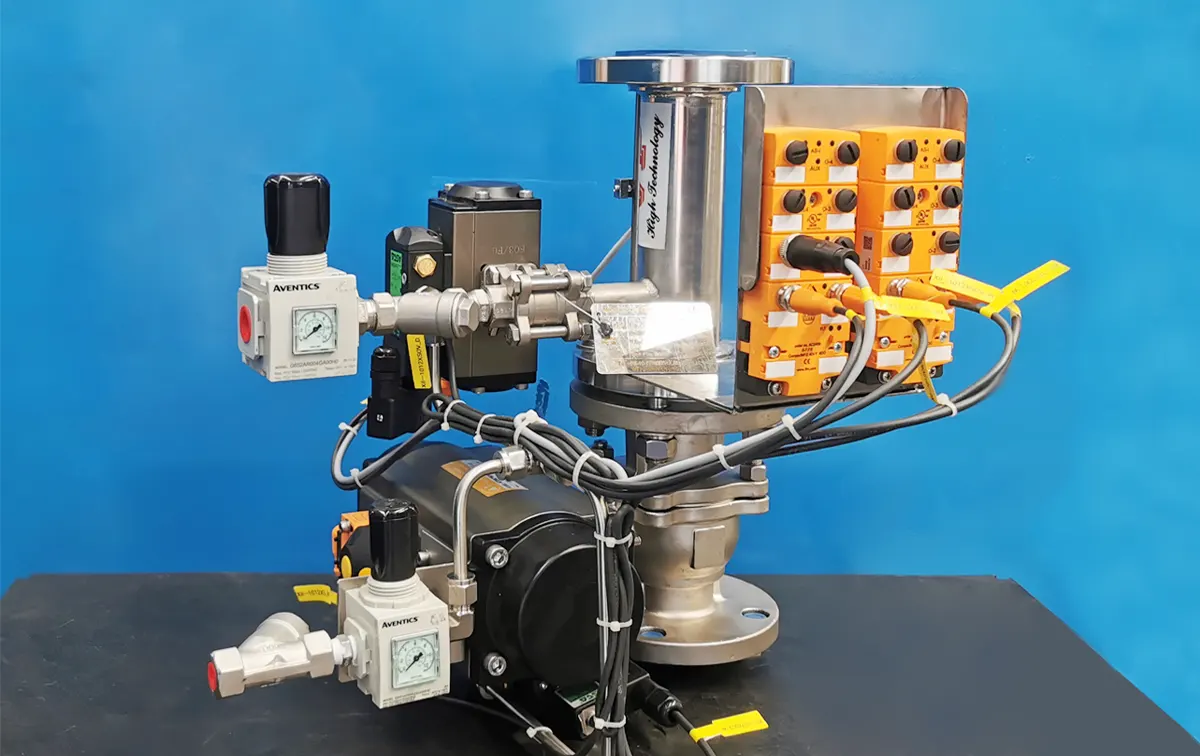

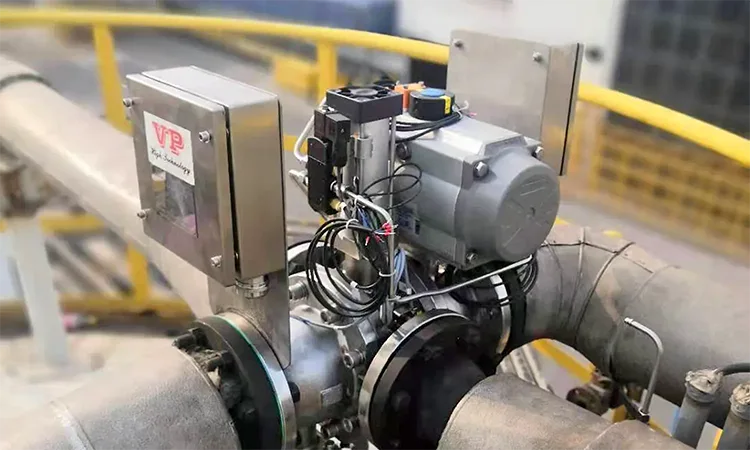

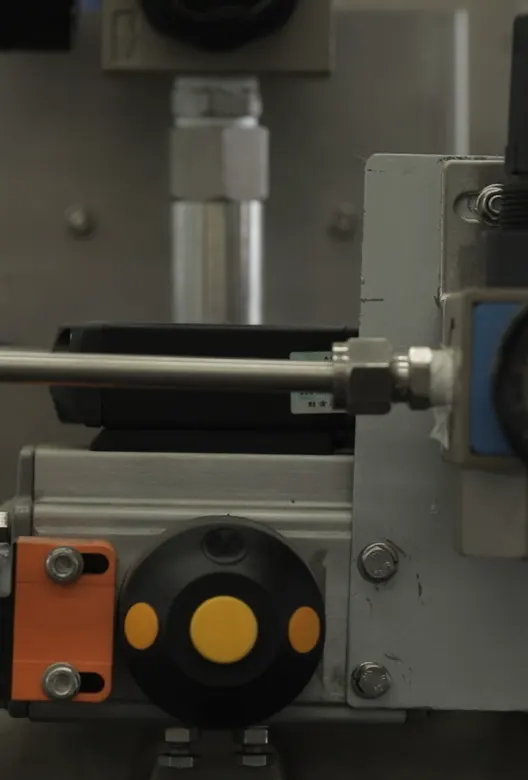

Pigging Station

Pig launcher & receiver for efficient, safe pipeline cleaning & product recovery

The PLC system provides centralized monitoring of the pigging station, including: 1. Product valve actuation status (open/closed); 2. Pneumatic control valve positions; 3. Real-time pig tracking through the pipeline. Pigging Station Utility Parameters Valve & Cylinder: 304SS, Power Supply: 24V DC, IP Rating: IP65, Design Pressure: 20 bar, Temperature Range: -30°C to 120°C, Average Ball Speed: 1.0-1.5 m/s, Actuation Pressure: 5-8 bar.

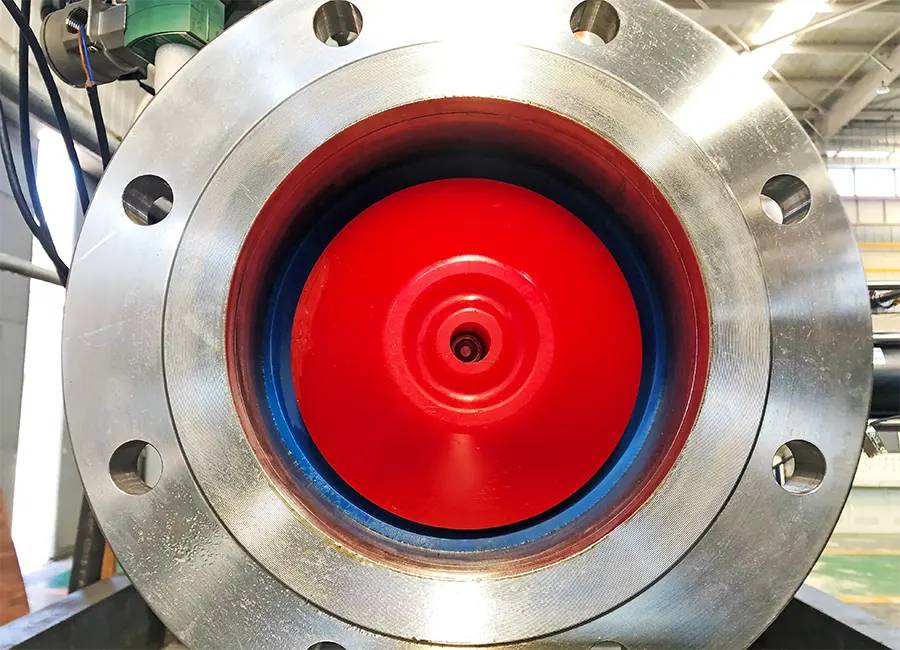

Magnetic Pigs

Made of elastic material, good sealing and wear resistance

A pigging pig is an elastic projectile with a diameter slightly larger than the pipeline’s inner diameter, made of elastic materials (such as rubber or polyurethane). Driven by the medium inside the pipeline (gas or liquid), it performs cleaning tasks. Typically cylindrical with conical ends for smooth passage through bends. Advanced sensors and control systems can be embedded to monitor position and speed in real time, enabling precise control and automation.

VP adopts advanced global polyurethane manufacturing technology and has developed solutions with different materials for various operating conditions, ensuring excellent elasticity, sealing, and wear resistance. Common materials include: Composite PU, Fluoroelastomer, Silicon Rubber, and Steel Brush.

-

Industrial-grade pigging pigs feature a modular, detachable structure (large-diameter body and lips) for easy maintenance and cost reduction.

-

Sanitary-grade pigging pigs use a seamless one-piece design to eliminate dead zones and prevent residue buildup.

More Pigs

How Does a Pigging Pig Work?

A pigging system uses pigging pigs to efficiently recover products, clean, or separate media inside pipelines. The operation steps are as follows:

1. Launch Preparation: Insert the pigging pig into the launching station and close the inlet valve.

2. Pig Propulsion: Use a driving medium (air, nitrogen, or cleaning liquid) to push the pig into the pipeline, where it scrapes the pipe wall and moves forward.

3. Product Recovery: The pig pushes residual liquid to the receiving station for recovery.

4. Pig Retrieval: After completing the task, the pig enters the receiving station and is collected through valve switching.

5. System Reset: The pig returns to the launching station, ready for the next operation.

Contact VP

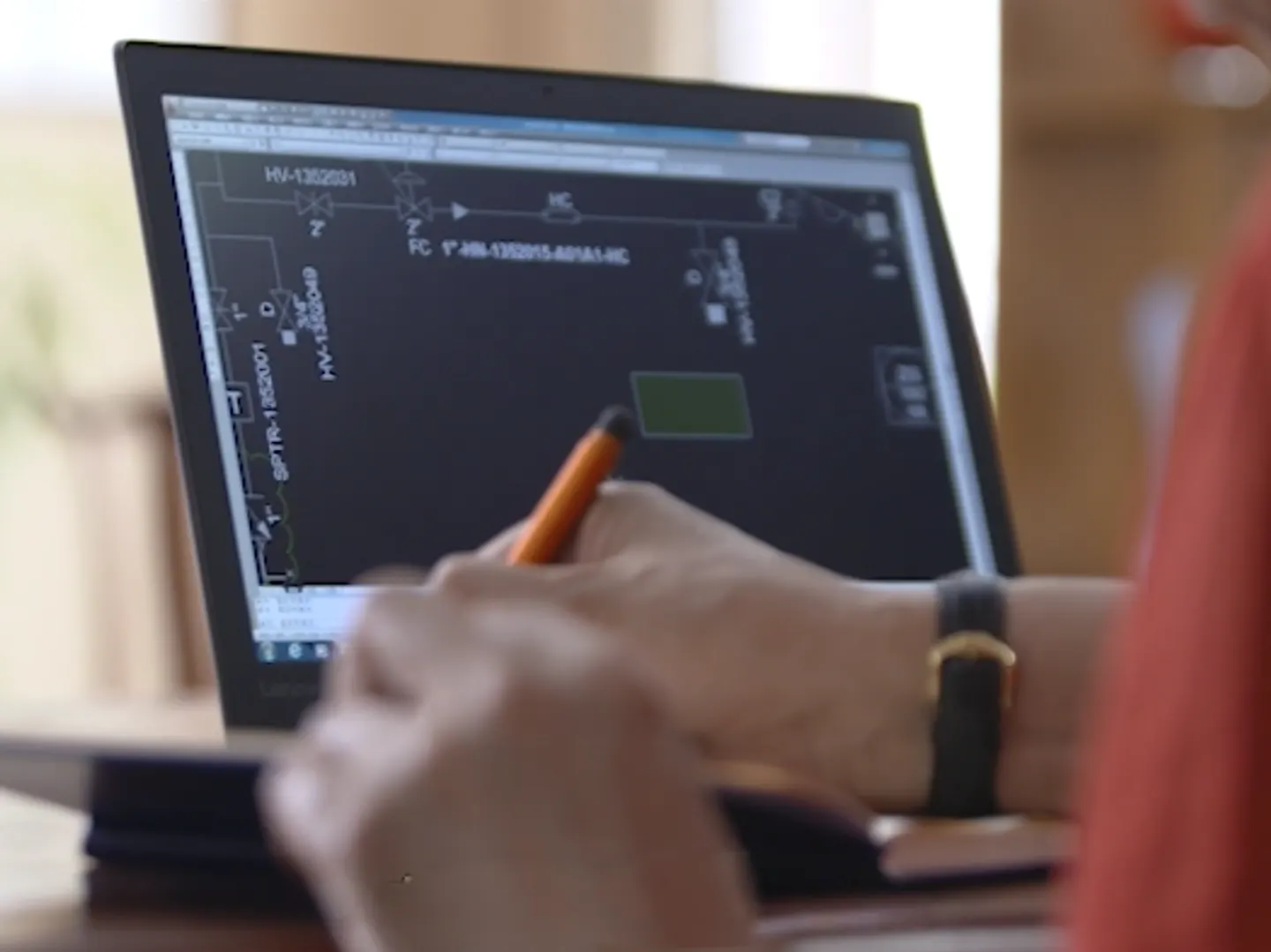

Control System

Smart Pigging Control: Automated, Safe & Efficient Operations

Pipeline Pigging Control System is an automated or semi-automated system designed to manage and control pipeline pigging operations. It ensures the safe and efficient operation of Pigs within pipelines, enabling them to perform tasks such as cleaning, inspection, isolation, or media transfer.

BJVP control center is equipped with a comprehensive set of software and hardware for DCS control, where control systems are tested before shipment,

Remote Control service and support is available to the customers, Compliant with Industrial Automation Safety Standards (IEC 61131-3).

The system adopts two mutually exclusive modes:

The system enforces a single control right through a permission interlock protocol to avoid signal conflicts and security risks caused by dual control operations.

Radius Elbows

Minimize resistance and wear for smooth pigging

Long Radius Elbows are necessary to ensure Pig move through smoothly in a pipping system. BJVP designs and manufactures long radius elbows in various types of materials.

Installation Specifications for Pigging System

1. The straight pipe segment between two elbows shall not be less than 10D;

2. Elbows must be equipped with straight pipe segments at both ends, with a length not less than 1.5D;

3. Elbows shall not connect directly to the pigging station; a straight pipe of ≥6D is required;

4. Standard angles of 45°, 60°, and 90° are recommended for elbows; non-standard angle elbows should not be used;

5. Elbows must have a bending radius of 5D or larger;

6. Each pigging station requires independent support, with supports every 4–6 m along the pipeline.

High Precision Seamless Pipeline Size Table

| Pipe Size |

Outer Diameter |

Inner Diameter |

Roundness Deviation |

Surface Finish |

| 1.5"-DN40 |

34.7mm |

38mm |

±0.15mm |

<0.8µm |

| 2"-DN50 |

60.3mm |

52.5mm |

±0.2mm |

<0.8µm |

| 3"-DN80 |

88.9mm |

77.9mm |

±0.3mm |

<0.8µm |

| 4"-DN100 |

114.3mm |

102.3mm |

±0.4mm |

<0.8µm |

| 6"-DN150 |

168.3mm |

154mm |

±0.6mm |

<0.8µm |

Customized Service and Customer Support

Professional Lubricant Blending Equipment China Manufacturer

Our Valued Partners

High brand reputation and industry recognition

Reduce your total cost of ownership

Pigging Systems and Plant-wide Automation Control Solutions

BJVP's pigging system adopts advanced technology and design concept, and the product performance is in a leading position in the industry. VP - Your Reliable Pigging System China Manufacturer.

About Us

-

Meet the needs of different customers

We provide customized pigging system solutions tailored to customers' piping systems, product characteristics and production needs. From pig design to drive system configuration and recovery unit selection, the actual needs of the customer are fully considered to ensure that the system is perfectly matched with the customer's requirements.

-

Professional technical and after-sales

Our professional team provides customers with a full range of technical support from system design, installation and commissioning to operation training. Provide timely after-sales service, including equipment maintenance, troubleshooting, and spare parts supply, to ensure the long-term stable operation of the pigging system.

-

Build a long-term relationships

We focus on long-term partnerships, and provide customers with continuous improvement solutions through continuous technological innovation and optimization. Regularly visit customers to understand the operation of the system and customer feedback, adjust and optimize the service content in a timely manner, ensuring satisfaction.