In pigging systems, the Pig Receiver (Receiver Station) plays a critical end-point role, serving as core equipment that ensures pipeline cleanliness, operational efficiency, and process safety. Precision-engineered and installed at pipeline terminals, it specializes in receiving, temporarily storing, and relaunching pigs.

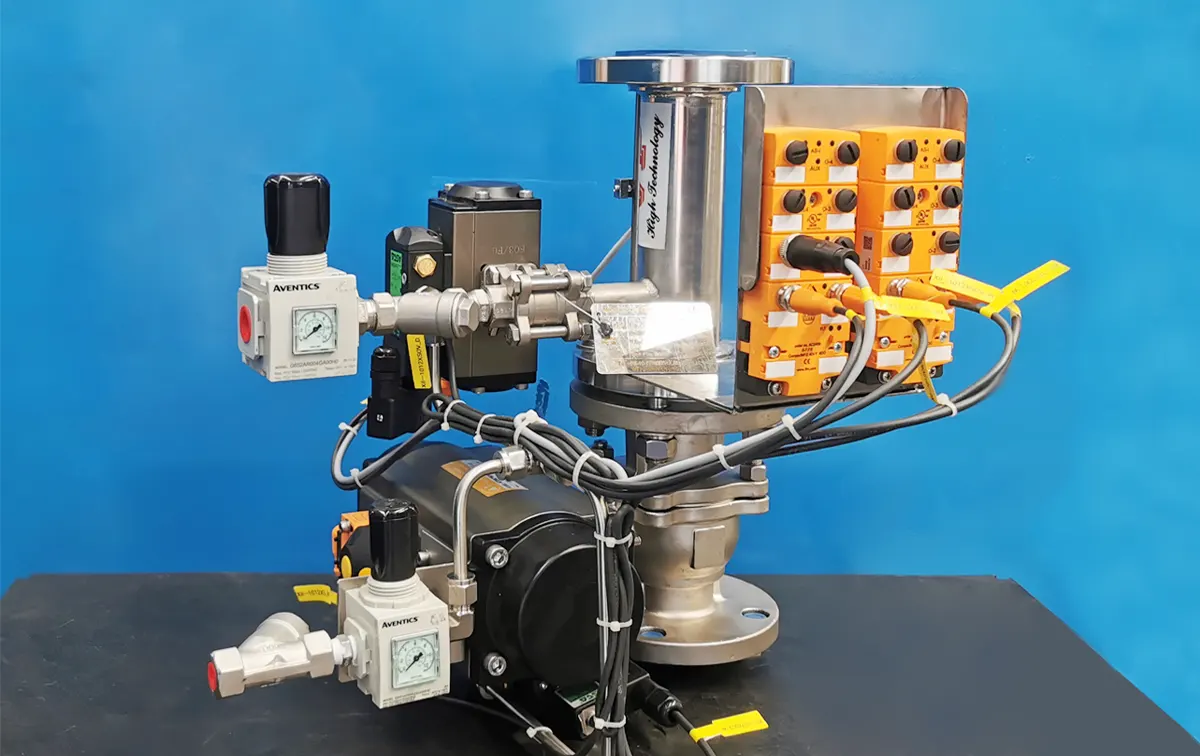

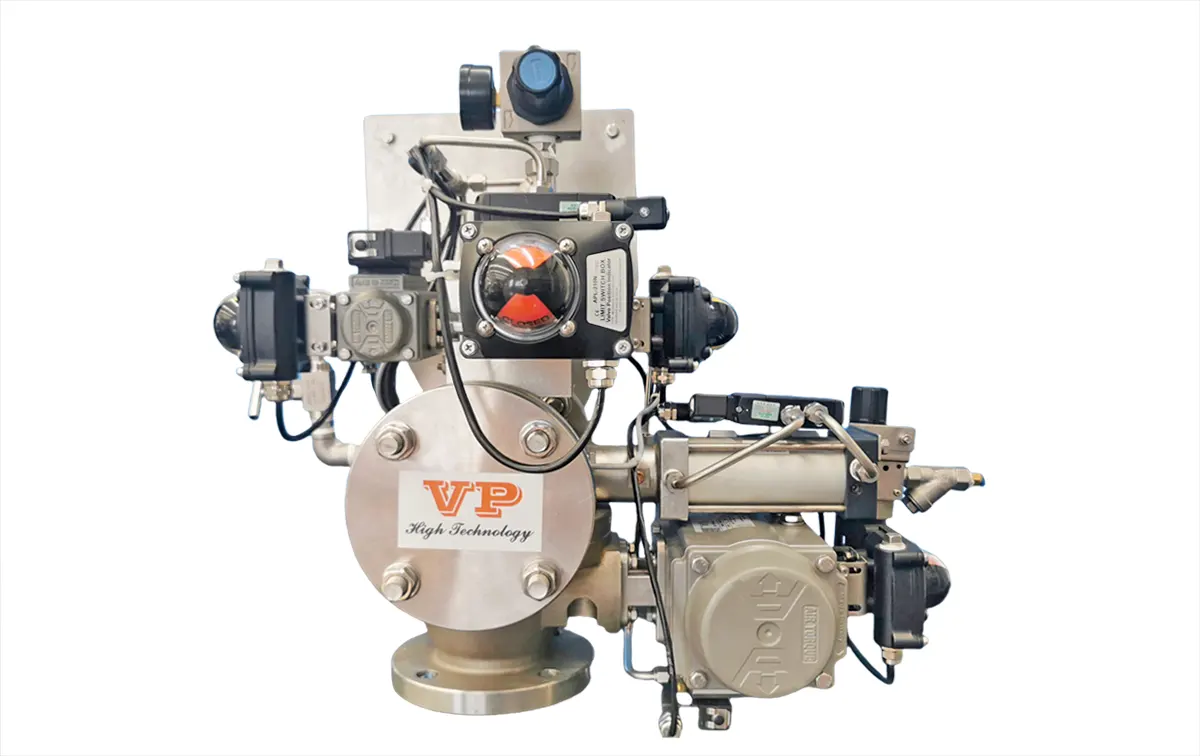

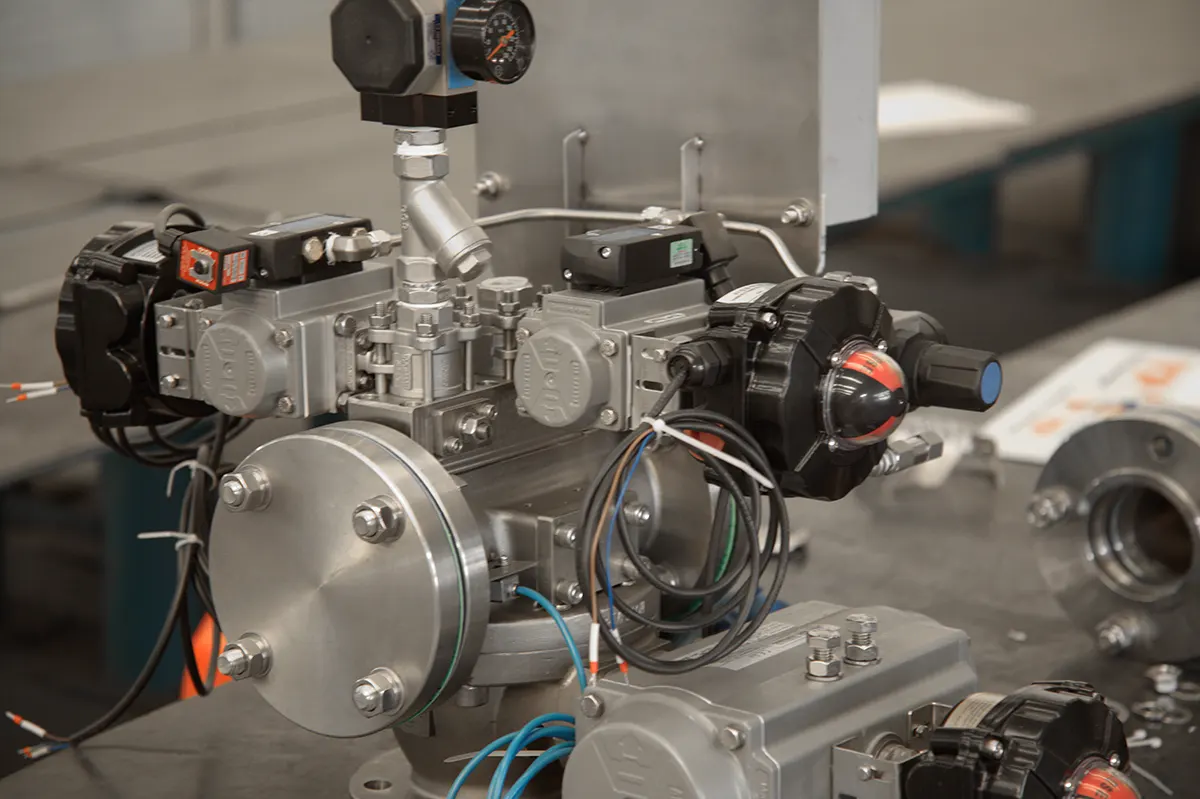

Some Pig Receiver are designed solely for receiving pigs, while most adopt an “integrated sending/receiving” concept, combining launching functionality into a highly compact unit. This symmetrical design features mirrored configurations with identical equipment modules, valve assemblies, and process pipelines on both ends, enabling seamless bidirectional pigging operations. The symmetric layout not only simplifies system configuration and enhances operational flexibility but also reduces construction costs and maintenance requirements, ensuring efficient and reliable pipeline cleaning. This standardized approach represents modern pigging station design, particularly suitable for pipelines requiring frequent two-way pigging operations.

Core Features

- Reliable Receiving & Storage: Acts as the final destination for pigs after pipeline cleaning, ensuring secure containment within specialized receiver barrels.

- Efficient Pig Return: Supports reverse pigging to launcher stations, enhancing operational flexibility and reducing downtime.

- Safe Pressure Relief: Integrated pressure release mechanisms ensure safe depressurization before maintenance access.

- Enhanced Cleaning Performance: The compression effect during pig entry intensifies scraping action, removing residual contaminants to guarantee pipeline cleanliness and maintain flow efficiency.

Key Technical Parameters (Adjustable per model)

| Parameter | Typical Range/Description |

|---|---|

| Design Pressure | 16Bar |

| Design Temperature | -30°C to +120°C (Material & seal dependent) |

| Bore Size (Receiver Barrel/Pipeline) | 1″ to 8″ |

| Main Material | Stainless Steel (304, 316L), Non-magnetic |

| Connection Type | Flange (WN, RF, RTJ), Threaded, TC Clamp |

| Valve Operation | Manual, Pneumatic, Hydraulic, Electric |

| Position Detection | Magnetic Sensors |

| Compliance Standards | Individually certified per customer requirements |

| Hygienic Certification | Optional, certified as per user specifications |

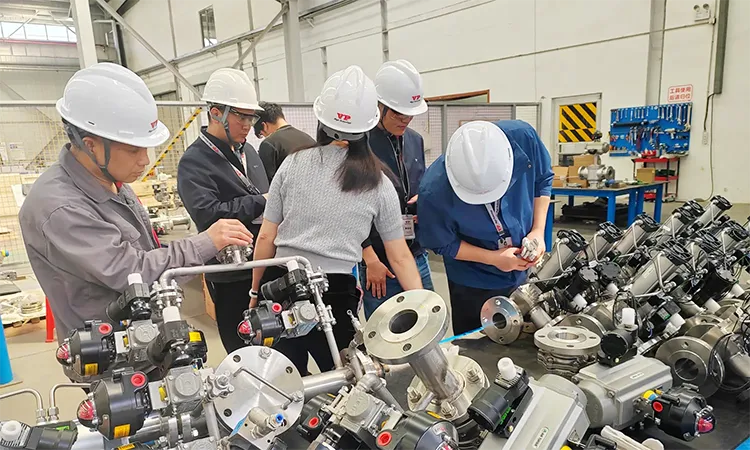

Custom Engineering

We tailor solutions to industry-specific needs (Oil & Gas, Chemical, Food, Pharma):

- Structural Customization: Skid-mounted or fixed designs. Receiver dimensions and pressure ratings (ANSI/ASME, PN) engineered to pipeline specs.

- Material Selection: Carbon steel, Stainless Steel (304/316L), Duplex steel – optimized for corrosion resistance and media purity.

- Functional Options: Standard safety valves, gauges, and drain valves. Optional pig indicators, ASME BPE quick-opening closures, automated PLC/DCS controls, and repressurization systems.

- Process Integration: Seamless connection with upstream/downstream operations.

Critical Safety Features

- Safety Interlocks: Pressure-locking mechanisms prevent access during pressurized operation.

- Impact-Resistant Support: Engineered to withstand pig impact forces and operational loads.

Applications

Widely used in product recovery and pipeline maintenance:

- Oil & Gas pipelines (Crude, Products, Natural Gas)

- Chemical/Petrochemical transfer lines

- Food, Beverage & Pharma CIP systems

- Marine & Offshore piping

Large Pig Launcher/Receiver Stations

Conventional pigging stations typically use piping smaller than NPS 8. Stations with piping NPS 10 or larger (10-inch, 12-inch) are classified as large, integrated launcher/receiver units. These are primarily used in long-distance pipelines, such as routes connecting railway stations to plants or terminals to factories. Installed at pipeline ends, they launch and receive pigs for pre-commissioning line cleaning and post-commissioning operations like wax removal, oil displacement, and scale cleaning.

Benefits of Our Pig Receivers

- Superior Pipeline Cleaning: Ensures optimal cleaning and product recovery.

- Enhanced Operational Safety: Secure pig containment and pressure management.

- Increased Efficiency: Pig return capability minimizes manual handling.

- Custom Solutions: Precisely engineered for your process requirements.

- Long-Term Reliability: International-standard manufacturing for sustained performance.

Upgrade your pigging system terminal performance and safety! Contact us for a custom Pig Receiver solution tailored to your pipeline.