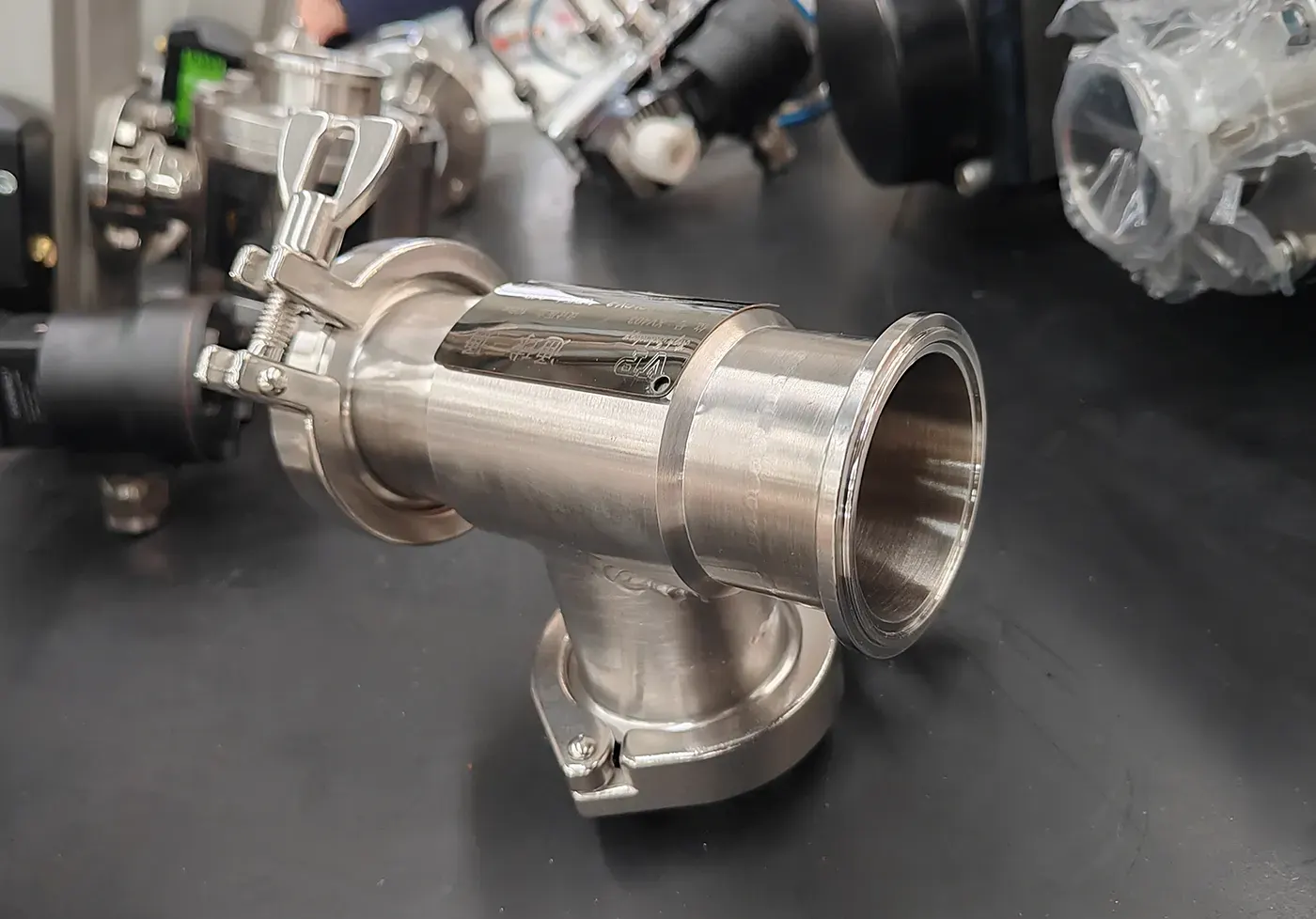

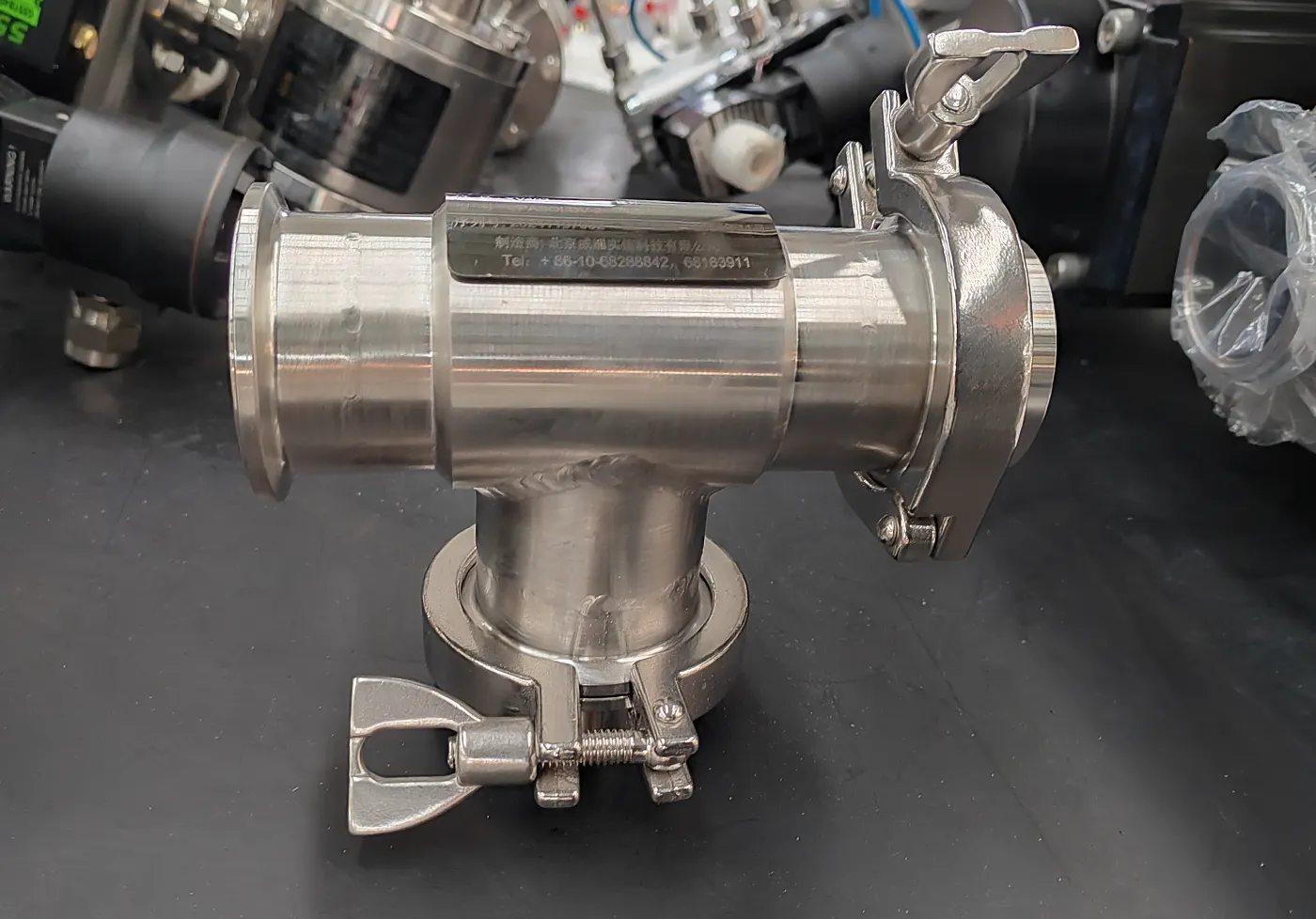

The Piggable Tee is a specialized pipeline component designed for Pipeline Pigging systems. Its primary function is to provide a horizontal, obstruction-free passage for the pipeline pig (scraper), ensuring smooth pigging operations. Unlike standard tees used solely for fluid flow diversion, a Piggable Tee allows the pig to pass through while maintaining tee functionality, and it retains significantly less residual material than conventional tees.

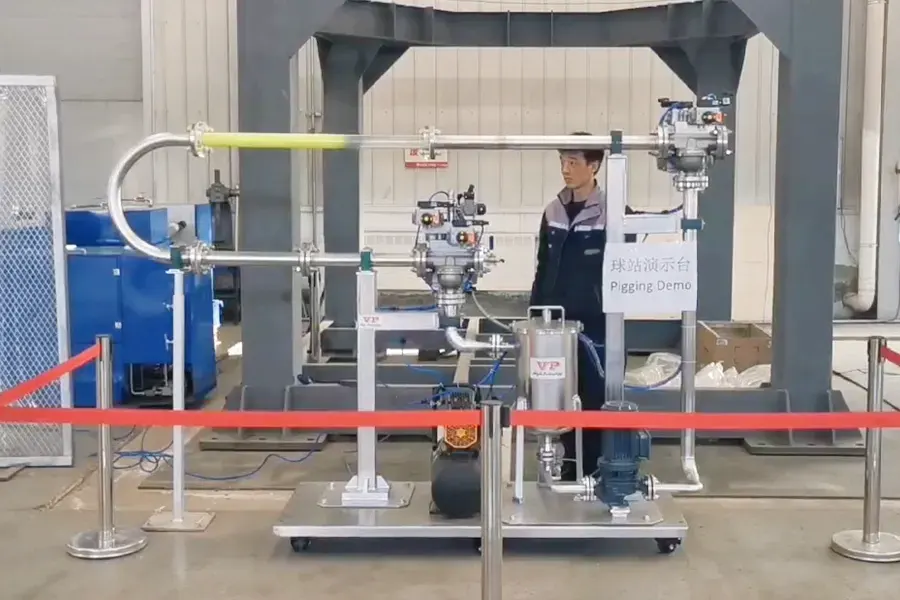

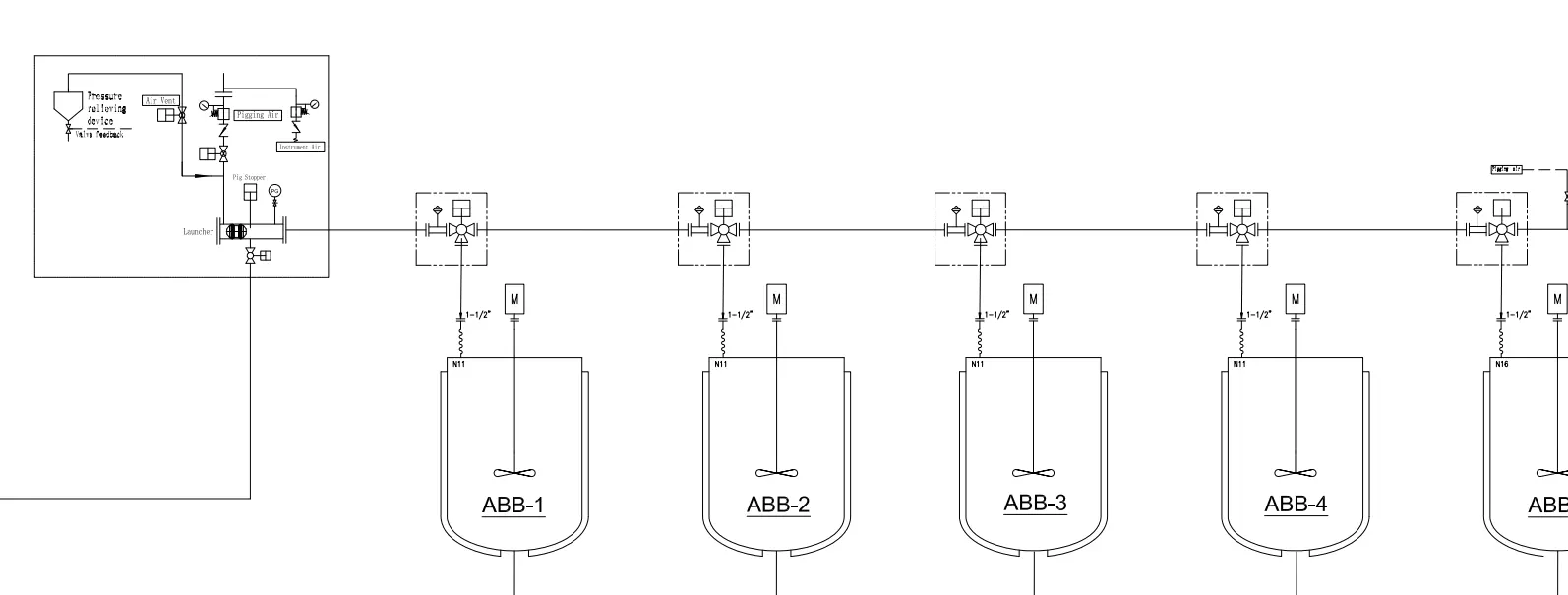

For Example: For multiple storage tanks holding the same material, product is delivered via pipeline. When delivering to a specific tank, the valve on that tank’s Piggable Tee is opened. After delivery, a pipeline pig is launched and travels horizontally through the tee, pushing residual material in the pipe back to the origin point.

In this diagram, material enters from the left, but the pipeline pig enters from the right, pushing residual material in the pipe back towards the origin. The pig does not stop at the Piggable Tee valve, while material enters the branch at this point.

Structural Features & Design Advantages

- Compact Branch Design: Beijing Weipu Piggable Tees feature a significantly shortened branch structure, optimizing space utilization and minimizing the volume for residual fluid retention.

- Obstruction-Free Internal Passage: The tee’s internal cavity is smooth and free from any internal obstructions or necking, ensuring pigs pass through without blockage. This prevents pig stalling and guarantees reliable pigging operations.

- Wide Material Selection: Available in materials like Carbon Steel and Stainless Steel to suit application requirements, including different media (corrosive, cleanliness demands) and pressure ratings.

Installation, Application & Working Principle

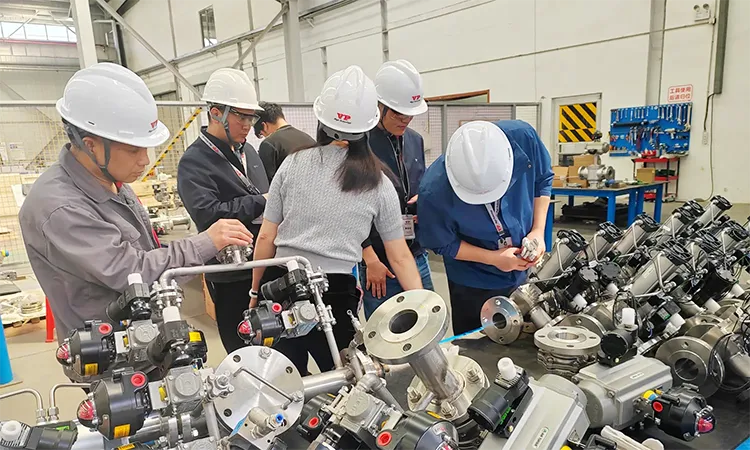

- Key Installation Points: Piggable Tees are typically installed with valves (such as ball valves or gate valves) at the product inlet (launch point) and outlet (receive point) of pigging systems.

- Simplified Pigging Solution: Can also be used in conjunction with a dedicated Stopper. The Stopper (often an insertable piston rod structure) is used to precisely halt the pig’s travel during pigging operations.

- Functionality: By operating the associated valves and/or stopper, the pig’s path is controlled: directing it into the main line for cleaning, or safely trapping it in the receiving chamber post-operation. Residual media or the pig itself can then be discharged via the drain port.

Beijing Weipu Piggable Tees, with their short branch and obstruction-free cavity design, deliver an efficient and reliable solution for pipeline pigging systems. They are widely applicable in scenarios with a single origin point and multiple destinations, offering a cost-effective alternative.