Our Services

Decades of Excellence in Pigging Design and Manufacturing

Lubricant Blending Equipment Manufacturing Since 1996

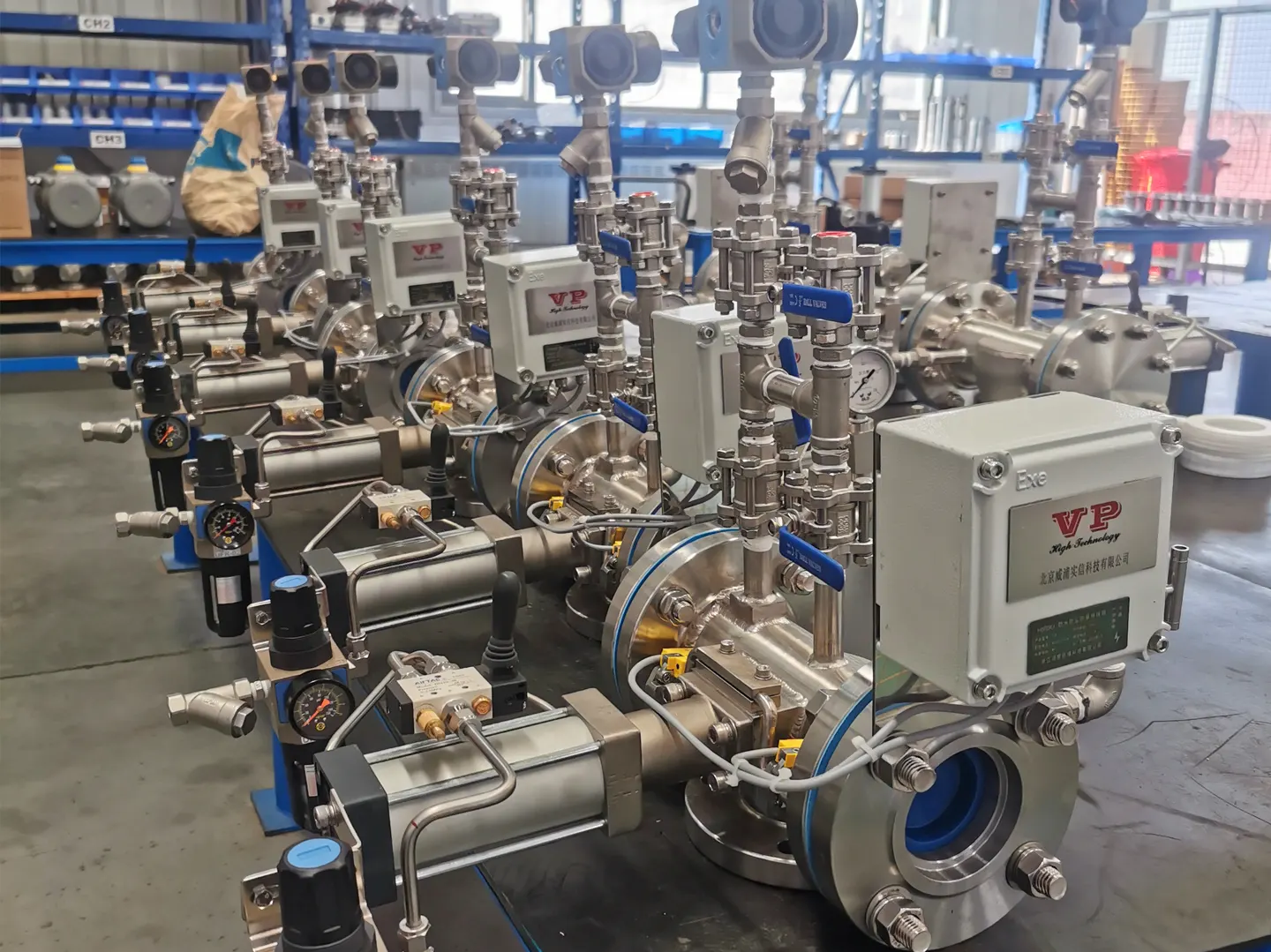

As a global leader in fully automated lubricant blending technology and equipment manufacturing, VP provides lubricant and grease producers with end-to-end process and turnkey equipment solutions for new plant construction, upgrades, and expansion projects. VP is CE certified in Europe.

The business main includes: Pigging System, Drum Decanting Units, Manifold System, Viscose Dissolver, Automatic Batch Blending, Simulate Metering Blending, DCS Control System, as well as High Viscosity Gear Pumps for high viscosity additives.

Customized Process Design

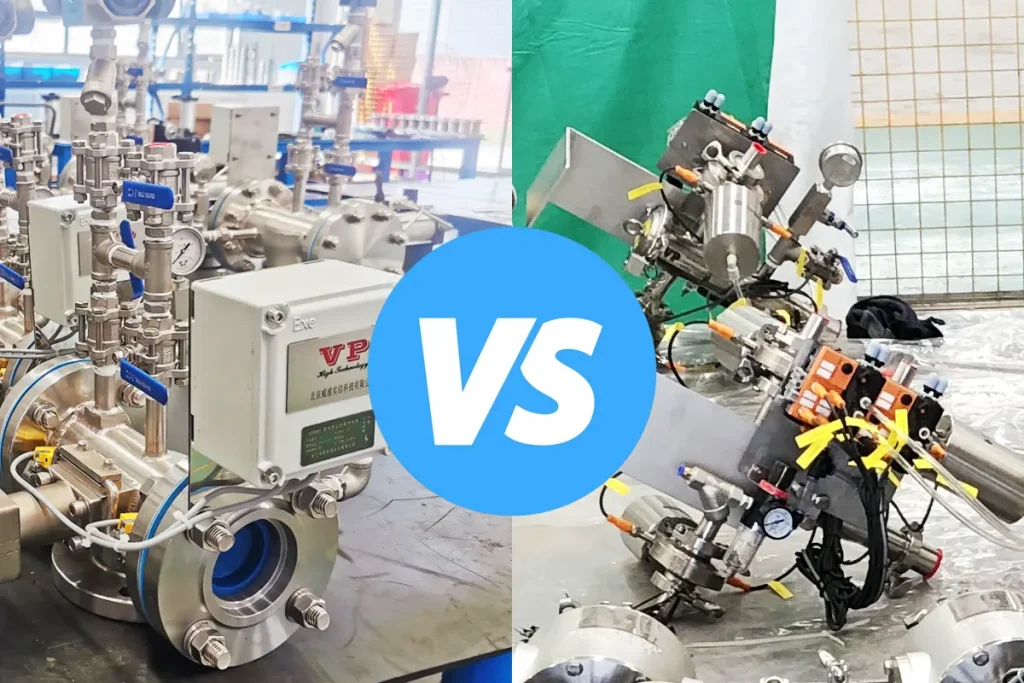

We provide engineered pigging solutions for lubricant and grease manufacturers, also widely used in food & beverage, biopharmaceutical, paint & coating, and daily chemical industries. From hygienic to industrial pigging, we offer a full product range and customized designs to ensure perfect integration with your production process, including pig launch/receive stations, pigs, long-radius bends, and DCS control systems.

With 30+ years of experience serving Shell, BP, and Sinopec, we deliver optimal pigging speed and cleaning efficiency, keeping residue ≤1 g/m. High recovery performance, reliable drive systems, and safe, practical receiving vessels ensure exceptional and lasting user value.

Technology Research & Development

We pay attention to technology research and development and innovation, and continuously invests resources in the research and development of new technologies and new products. Through cooperation with universities, scientific research institutions and industry experts, combined with practical application requirements, we continue to improve the technical performance and functional characteristics of the pigging system.

Amid evolving technologies and changing market demands, BJVP continues to increase R&D investment, driving innovation and upgrades in pigging systems, and developing smarter, more efficient solutions to enhance product recovery efficiency and system stability.

Installation & Training

We provide complete turnkey installation and operator training programs for your pigging system. Our certified engineers handle every phase of implementation:

Installation & Commissioning: 1. On-site assembly of pig launchers/receivers and pigging systems; 2. Integration with your existing pipeline network and control systems; 3. Pressure testing and performance validation.

Operator Training: 1. Detailed operation procedures for daily production; 2. Maintenance methods for pigs and related components; 3. Troubleshooting common issues and safety protocols.

Reliable After-sales Support for Your Pigging Project

We has a professional technical team to provide customers with a full range of technical support from system design, installation and commissioning to operation training. Provide timely after-sales service, including equipment maintenance, troubleshooting, and spare parts supply, to ensure the long-term stable operation of the pigging system.

We always focus on long-term cooperation with customers, and provides customers with continuous improvement solutions through continuous technological innovation and optimization. Regularly visit customers to understand the operation of the system and customer feedback, adjust and optimize the service content in a timely manner, and ensure customer satisfaction.

About VP-

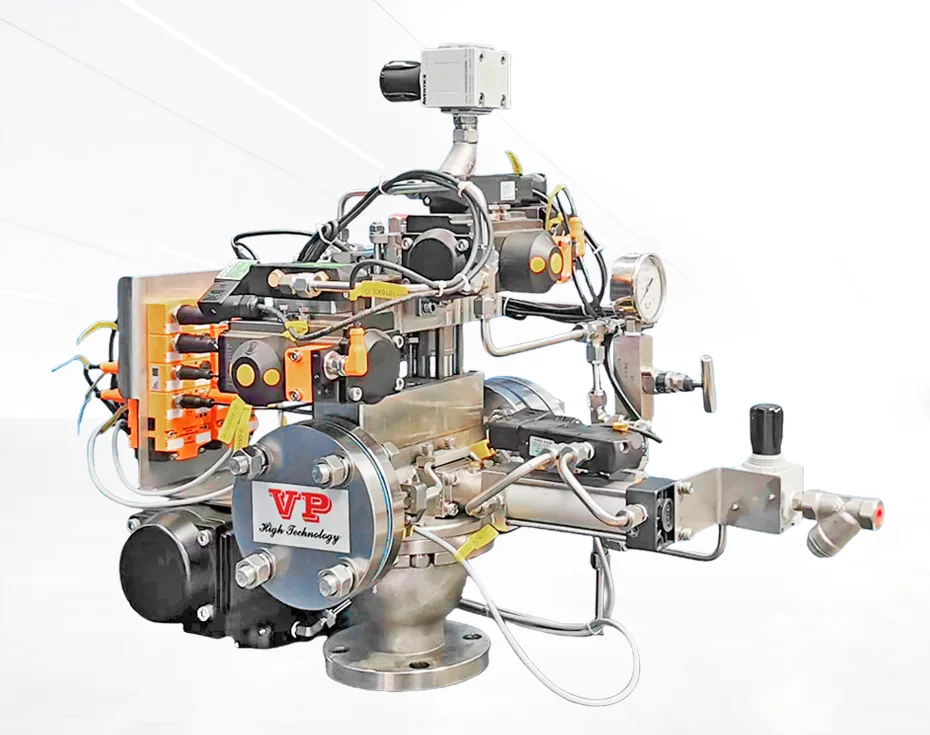

The Pig Launcher Station is a critical component in modern industrial pipeline cleaning and product recovery. More than a valve, it integrates power connection, pig storage...

Learn MoreLauncher Station

-

The Pig Receiver Station ensures precise pig capture at pipeline endpoints. Its specialized design reliably intercepts pigs and enables back-blowing to launchers...

Learn MoreReceiver Station

-

Add efficiency to your Pipeline Cleaning and Product Recovery with Our Pigging System. VP Pigging System is automated industrial solution integrating...

Learn MorePigging Solutions

-

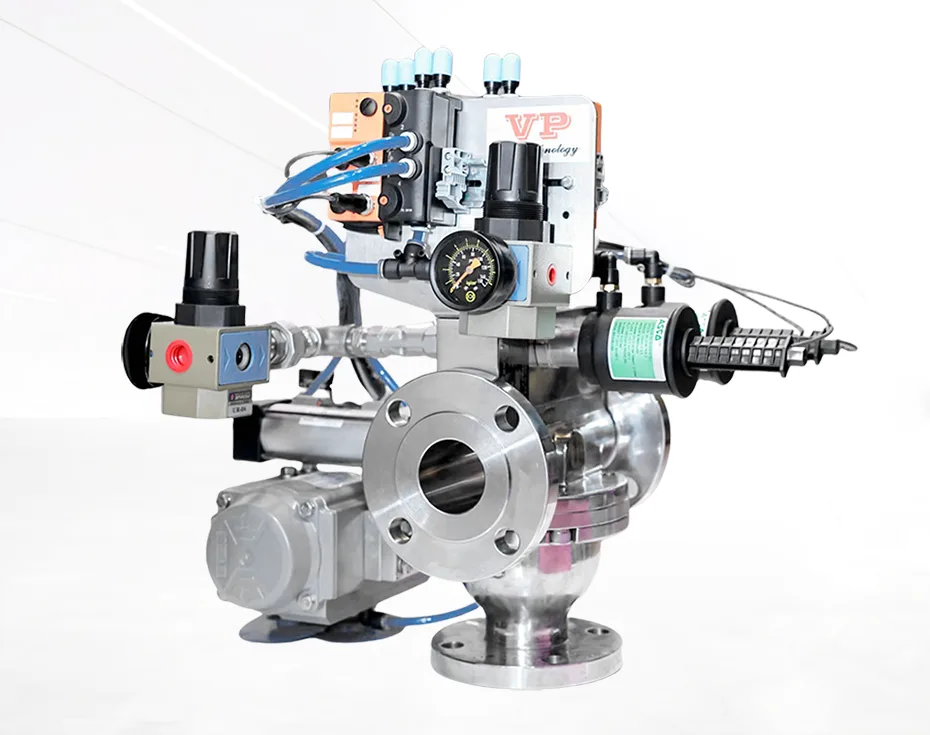

Piggable ball valves feature a specialized full-bore design matching pipeline internal diameter (ID), ensuring smooth pig passage and eliminating product residue.

Learn MorePiggable Valve