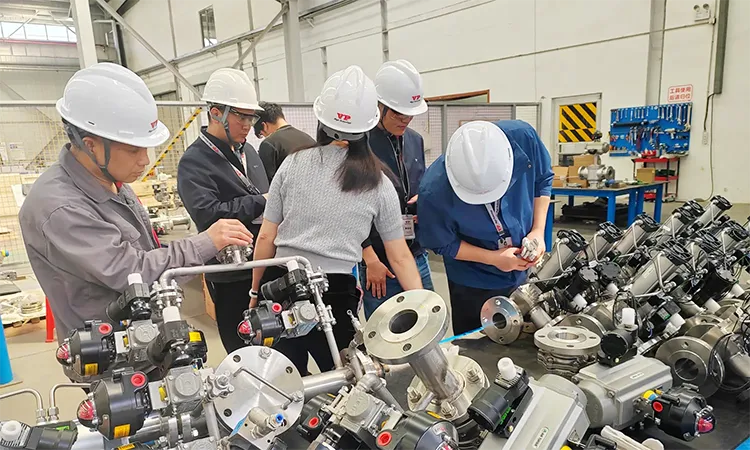

The pigging system middle station is a critical facility in pipeline pigging operations, designed as a fast pig launcher and receiver at designated intermediate locations. As a key process node, it enables efficient pig launching, pig receiving, and full-process monitoring. VP middle stations feature modular design and intelligent control, ensuring safe, efficient, and reliable operation.

Functions and Advantages of a Pigging System Middle Station

Accurate and Efficient Pigging Operations

The middle station allows precise launching and receiving of pipeline pigs and products, providing intermediate stop points beyond the main launcher and receiver stations. This significantly reduces pipeline downtime and improves operational efficiency.

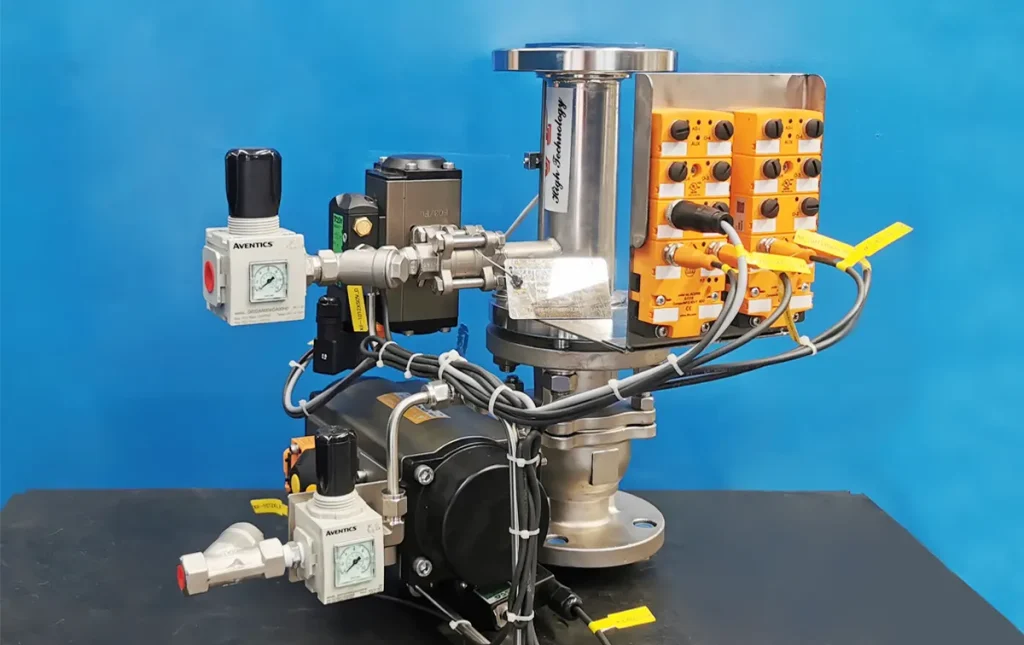

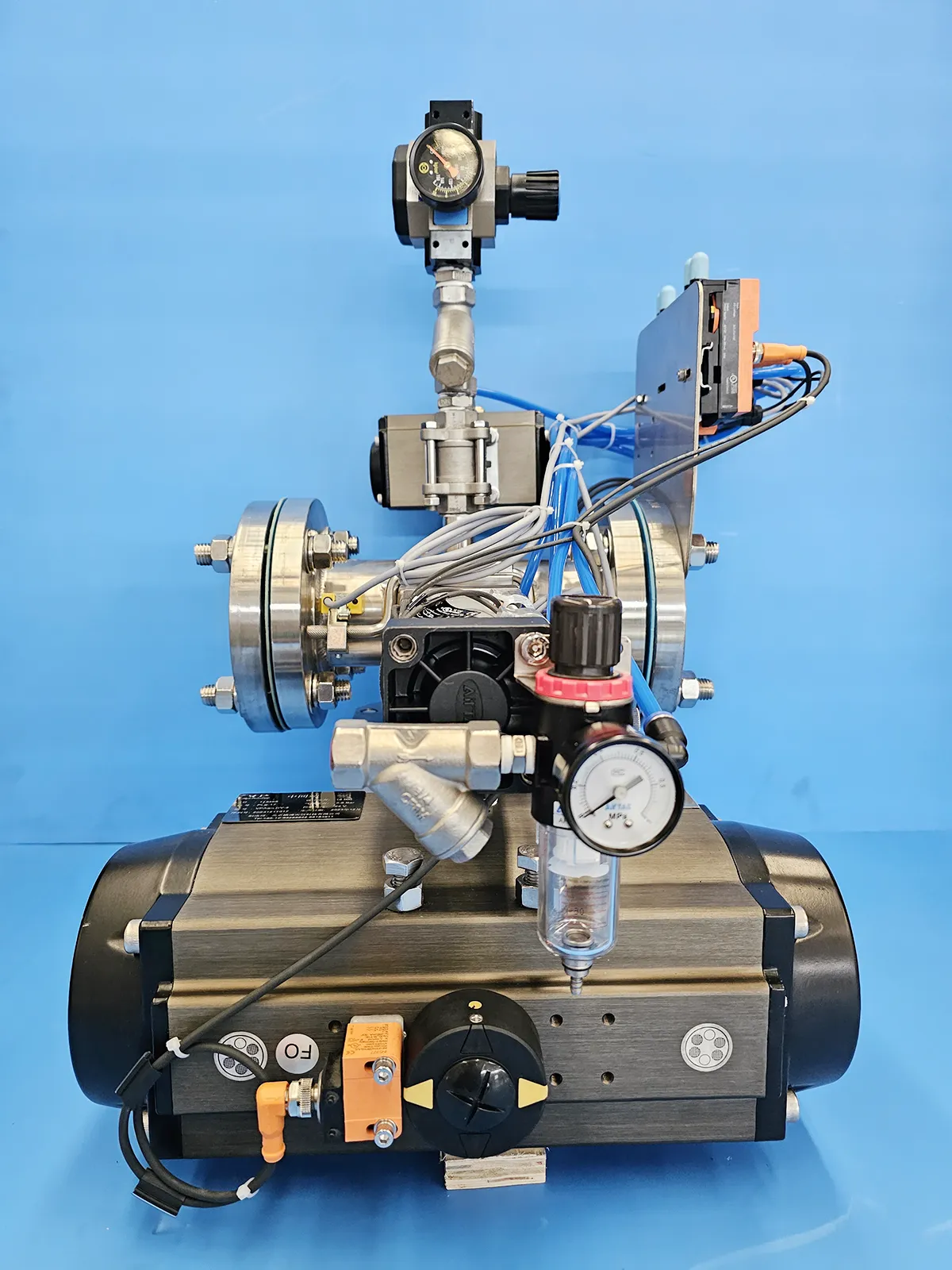

Intelligent Process Monitoring

Integrated pressure and flow monitoring, along with pig signaling indicators, enable real-time tracking of pipeline conditions and pig position, ensuring full visibility and control during pigging operations.

Advanced Safety Design

The system adopts high-pressure sealing structures combined with comprehensive safety interlocks, effectively minimizing operational risks and ensuring personnel, equipment, and environmental safety.

Excellent Compatibility and Scalability

With a modular configuration, the middle station can be easily adapted to different pipe diameters, pressure ratings, and media characteristics, offering strong system compatibility and future expandability.

Industries Served by VP Pigging System Middle Stations

Coatings Industry

Enables precise separation of different product batches, effectively eliminating cross-contamination, improving product recovery rates, and reducing material waste.

Chemical Industry

Efficiently removes chemical residues inside pipelines, preventing cross-contamination and ensuring safe, continuous production processes.

Oil & Petroleum Industry

Used to remove wax, scale, and deposits from oil pipelines, maintaining high flow efficiency and ensuring stable pipeline operation.