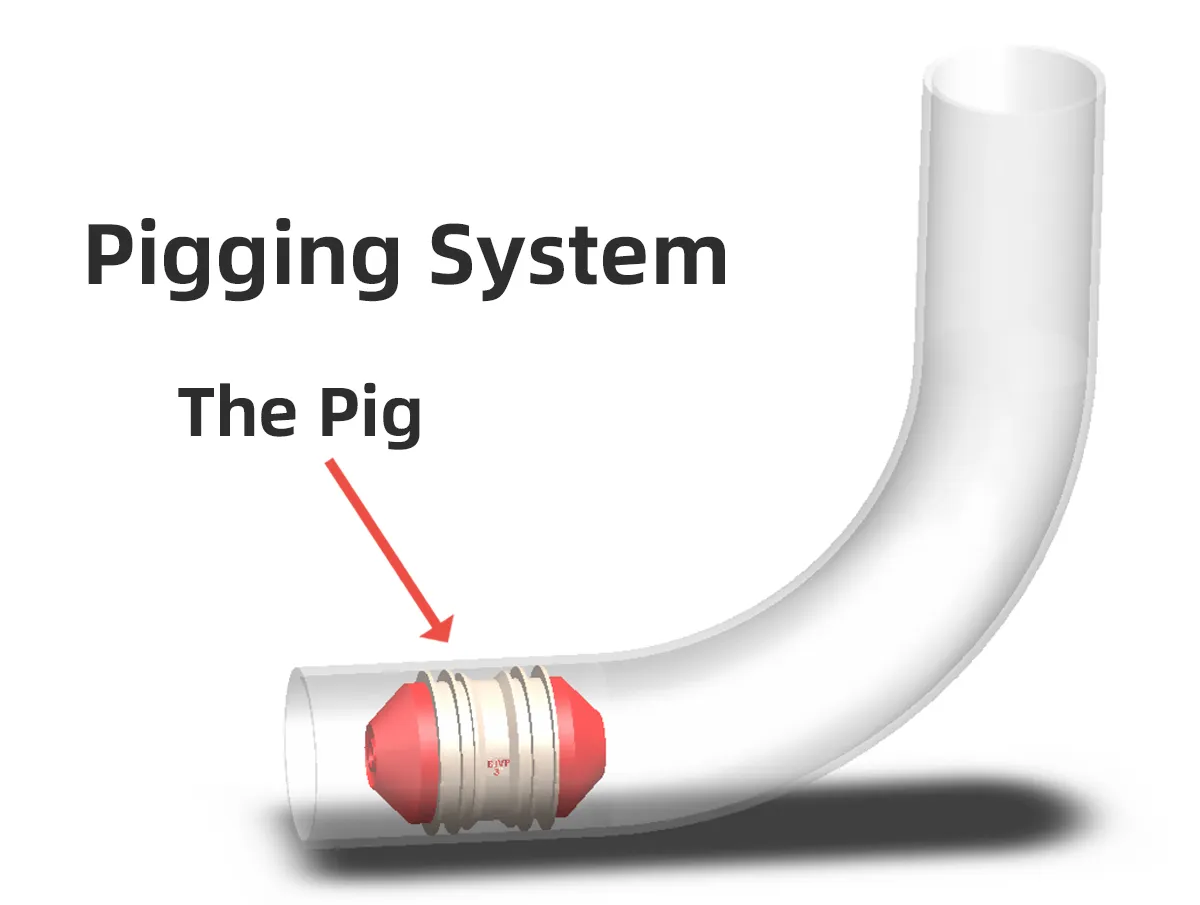

Pigging Pig is a key component in pipeline cleaning systems, used for cleaning and recovering residuals within pipelines. Driven by gas or liquid, the pig moves through the pipeline, performing cleaning tasks. Its diameter is slightly larger than the internal diameter of the pipe to ensure a tight contact with the pipe wall, efficiently cleaning and recovering residuals.

BJVP Sanitary Integrated Pigging Pig is designed to meet the stringent hygiene standards of industries like food, pharmaceuticals, and chemicals. Made from food-grade silicone and featuring an integrated soft magnet, it ensures efficient cleaning and product recovery inside the pipeline. This pigging ball seamlessly works with the BJVP sanitary pigging system to effectively remove residues, improve production efficiency, and reduce cross-contamination risks.

The pigging ball is typically available in sizes ranging from 2 inches to 8 inches, with customized sizes such as 1.5 inches and 2.5 inches available for specific industry needs. Both material and size can be adjusted based on the user’s specific conditions, ensuring tailored solutions for clients. The built-in magnet ensures the pig’s precise positioning within the pipeline, allowing for accurate operation, enhancing cleaning efficiency, and extending the pipeline’s lifespan.

The BJVP Sanitary Integrated Pigging Pig is designed to meet the strictest hygiene standards, preventing product contamination, reducing solvent usage, lowering production costs, and offering high durability and reliability. It is ideal for various sanitary pipeline cleaning needs, helping businesses ensure efficient and safe production processes.